FGT think your best choice in the future

System Integration Designers in FGT

PFM220 Type: Glass Rotor Area Flow Meter

- Fluid Type:Corrosive gases and corrosive liquids

- Contact material:

- brass or stainless steel

- Sealing Nitrile or Viton

- Float stainless steel or onyx or polymethylmethacrylate plastic

- Connector:brass or stainless steel

- Connection size:Metal Fittings: M10 & Hose Fittings (2-Ø8)

- Installation: Back to Back

- Operating pressure:≦2Mpa(20bar)@38℃(100℉).

- Maximum temperature:~+60℃

- Accuracy:±4% of full scale (±2.5% of full scale for DN6~10mm)

Variable Area Flowmeter

Introduce

A variable area flowmeter is a differential pressure flowmeter. These are simple and versatile devices for measuring the flow of liquids, gases and steam. They work with a fairly constant pressure drop. In these types of flow meters, a direct visual indication of flow is given by the position of a float, piston or vane. The position of their floats, pistons or vanes changes as rising flow rates open up a larger flow area for the flowing fluid to pass through. When flow is reduced, gravity or springs are used to return the flow element to its static position. Gravity flow meters must also be installed in a vertical position, whereas spring-loaded flow meters can be installed in any position. Each variable area flow meter has a local indicator. In addition, they can be equipped with position sensors and transmitters, i.e. pneumatic, electronic, digital or fiber optic type sensors, for linking to remote displays or controls.

Types of Variable Area Flow Meters

Variable area flow meters are available in a variety of designs:

- Rotameter (with float in conical tube)

- Orifice/rotameter combination, i.e. bypass rotameter

- Open channel variable gate

- Cone Quick Plug, and

- Vane or Piston Design

Rotameter

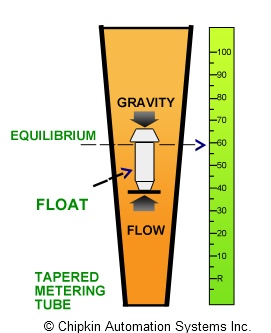

Rotameters are the most widely used variable area flowmeters. A rotameter basically consists of a vertically oriented glass or plastic conical tube and a metering float that can move freely within the tube. Rotameters, although classified as differential pressure units, are actually constant differential pressure devices. Flange end fittings provide an easy way to install them in pipes. The float is free to rest on the bottom of the tube when there is no fluid flow. When the liquid enters the bottom of the tube, the metering float begins to rise. The position of the float varies directly with the flow. The precise position of the float is where the pressure difference between the upper and lower surfaces balances the weight of the float. The greater the flow, the higher the float is lifted. In the case of a fluid, the float rises due to a combination of the buoyancy of the liquid and the velocity head of the fluid, whereas with a gas the buoyancy is negligible and the float responds to a large extent to the velocity head. The figure below shows a typical rotameter:

main feature

- In a rotameter, the height of the float indicates flow.

- Rotameter tubes can be calibrated and indexed with the appropriate flow units.

- Rotameters typically have turndown ratios as high as 12:1.

- Accuracy may be up to 1% of full scale rating.

- Rotameter tubes can be made of glass, metal or plastic.

- Tube diameters range from 1/4 to greater than 6 in.

- In safe applications, such as air or water, rotameter tubes can be made of glass, while in situations where a rupture could lead to an unsafe condition, they come with metal tubes.

- Additionally, for higher pressures and temperatures above the practical range of glass, metal tube rotameters are used.

- Plastic tube rotameters are medium cost rotameters. Also, they are ideal for applications involving corrosive fluids or deionized water.

- Almost all rotameters are insensitive to viscosity changes. The most sensitive are extremely small rotameters with spherical floats, while larger rotameters are less sensitive to viscosity effects.

- Rotameters including magnetic floats can be used for alarm and signaling functions.

- Since the flow rate can be read directly on the scale installed next to the tube, no auxiliary flow reading device is required. However, an automatic sensing device can still be used to sense the float level and send a flow signal if desired.

- Each float position corresponds to a specific flow rate for a specific fluid density and viscosity. Therefore, sizing the rotameter for each application is critical. If properly sized, the flow rate can be determined by matching the float position to a calibrated scale on the outside of the rotameter.

- Many rotameters have built-in valves for manual flow adjustment.

- Various shapes of floats are available for various applications. One early float design had slots, which caused the float to rotate for stabilization and centering. Due to this rotation of the float, the term rotameter was coined.

Dimensions of the rotameter

Rotameters typically have calibration data and direct reading scales for air or water or both. In order to size a rotameter for other services, the actual flow must first be changed to a standard flow. In the case of liquids, the standard flow should be the water equivalent in gpm, while when it comes to gas, the expected standard flow is the air flow in standard cubic feet per minute (scfm).

Rotameter manufacturers provide tables listing standard water equivalent gpm and air scfm values. They should also provide available slide rules, nomograms, or computer software, which is often required for sizing rotameters.

advantage

The main advantages of the rotameter are as follows:

- low cost

- simple design

- low pressure drop

- widely used

- Linear output

| Application | Flow Meter |

|---|---|

| Types of | Mechanical |

| Installation method | mouth, plate |

size

|

|

| No needle valve | with needle valve |

| Flow range | Dimensions (mm) | Hose Fittings | metal pipe joint | Mounting holes | |||||

| coding | A | B | C | D | E | M | N | ||

| 20XXX | 26 | 136 | 50 | 24.0 | <50 | 116 | ψ8 | M10x1 | 2-ψ11 |

| 21XXX | 28 | 136 | 56 | 27.5 | <52 | 116 | ψ8 | M10x1 | 2-ψ11 |

| 22XXX | 28 | 136 | 58 | 29.5 | <55 | 116 | ψ10 | M10x1 | 2-ψ11 |

| 23XXX | 28 | 160 | 60 | 29.5 | <55 | 140 | ψ11 | M10x1 | 2-ψ11 |

Application field

Variable Area Flowmeter

Introduce

A variable area flowmeter is a differential pressure flowmeter. These are simple and versatile devices for measuring the flow of liquids, gases and steam. They work with a fairly constant pressure drop. In these types of flow meters, a direct visual indication of flow is given by the position of a float, piston or vane. The position of their floats, pistons or vanes changes as rising flow rates open up a larger flow area for the flowing fluid to pass through. When flow is reduced, gravity or springs are used to return the flow element to its static position. Gravity flow meters must also be installed in a vertical position, whereas spring-loaded flow meters can be installed in any position. Each variable area flow meter has a local indicator. In addition, they can be equipped with position sensors and transmitters, i.e. pneumatic, electronic, digital or fiber optic type sensors, for linking to remote displays or controls.

Types of Variable Area Flow Meters

Variable area flow meters are available in a variety of designs:

- Rotameter (with float in conical tube)

- Orifice/rotameter combination, i.e. bypass rotameter

- Open channel variable gate

- Cone Quick Plug, and

- Vane or Piston Design

Rotameter

Rotameters are the most widely used variable area flowmeters. A rotameter basically consists of a vertically oriented glass or plastic conical tube and a metering float that can move freely within the tube. Rotameters, although classified as differential pressure units, are actually constant differential pressure devices. Flange end fittings provide an easy way to install them in pipes. The float is free to rest on the bottom of the tube when there is no fluid flow. When the liquid enters the bottom of the tube, the metering float begins to rise. The position of the float varies directly with the flow. The precise position of the float is where the pressure difference between the upper and lower surfaces balances the weight of the float. The greater the flow, the higher the float is lifted. In the case of a fluid, the float rises due to a combination of the buoyancy of the liquid and the velocity head of the fluid, whereas with a gas the buoyancy is negligible and the float responds to a large extent to the velocity head. The figure below shows a typical rotameter:

main feature

- In a rotameter, the height of the float indicates flow.

- Rotameter tubes can be calibrated and indexed with the appropriate flow units.

- Rotameters typically have turndown ratios as high as 12:1.

- Accuracy may be up to 1% of full scale rating.

- Rotameter tubes can be made of glass, metal or plastic.

- Tube diameters range from 1/4 to greater than 6 in.

- In safe applications, such as air or water, rotameter tubes can be made of glass, while in situations where a rupture could lead to an unsafe condition, they come with metal tubes.

- Additionally, for higher pressures and temperatures above the practical range of glass, metal tube rotameters are used.

- Plastic tube rotameters are medium cost rotameters. Also, they are ideal for applications involving corrosive fluids or deionized water.

- Almost all rotameters are insensitive to viscosity changes. The most sensitive are extremely small rotameters with spherical floats, while larger rotameters are less sensitive to viscosity effects.

- Rotameters including magnetic floats can be used for alarm and signaling functions.

- Since the flow rate can be read directly on the scale installed next to the tube, no auxiliary flow reading device is required. However, an automatic sensing device can still be used to sense the float level and send a flow signal if desired.

- Each float position corresponds to a specific flow rate for a specific fluid density and viscosity. Therefore, sizing the rotameter for each application is critical. If properly sized, the flow rate can be determined by matching the float position to a calibrated scale on the outside of the rotameter.

- Many rotameters have built-in valves for manual flow adjustment.

- Various shapes of floats are available for various applications. One early float design had slots, which caused the float to rotate for stabilization and centering. Due to this rotation of the float, the term rotameter was coined.

Dimensions of the rotameter

Rotameters typically have calibration data and direct reading scales for air or water or both. In order to size a rotameter for other services, the actual flow must first be changed to a standard flow. In the case of liquids, the standard flow should be the water equivalent in gpm, while when it comes to gas, the expected standard flow is the air flow in standard cubic feet per minute (scfm).

Rotameter manufacturers provide tables listing standard water equivalent gpm and air scfm values. They should also provide available slide rules, nomograms, or computer software, which is often required for sizing rotameters.

advantage

The main advantages of the rotameter are as follows:

- low cost

- simple design

- low pressure drop

- widely used

- Linear output

Order model

| Order model | ||||||||||

| PFM220 | coding | fluid type | ||||||||

|

|

A | Liquid | ||||||||

| B | Gas | |||||||||

|

|

coding | Flow range | ||||||||

| 2XXXX | Please See Flow Range Table | |||||||||

|

|

coding | material | ||||||||

| 1 | Normal Type | |||||||||

| 2 | Anticorrosive Type | |||||||||

|

|

coding | needle valve | ||||||||

| W | with Needle Valve | |||||||||

| N | without Needle Valve | |||||||||

|

|

coding | Installation method | ||||||||

| BB | Back to Back | |||||||||

|

|

coding | Printing customer logos | ||||||||

| F | FGT | |||||||||

|

Printing customer Logo | |||||||||

| PFM220 | Complete order model | |||||||||

| *Note: The use of customized labels requires a single model to place an order of more than 100 per year | ||||||||||