FGT think your best choice in the future

System Integration Designers in FGT

- 2022-04-10

- 3:06 pm

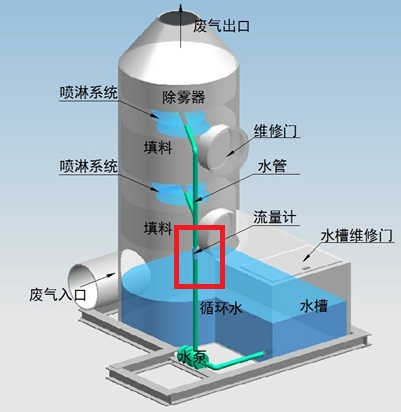

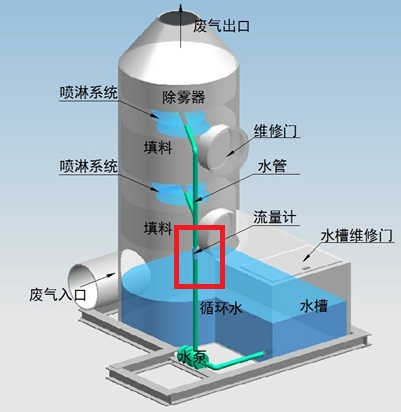

Organic waste gas treatment washing tower, acid mist purification tower improvement project

What are spray towers, washing waste gas towers, washing towers, and acid mist treatment towers?

What are the functions of the waste gas treatment scrubber

1. Waste gas treatment tower,

1)Spray tower, water washing waste gas tower, washing tower, acid mist treatment tower, its main function is to reduce the concentration of exhaust gas through washing, and let the exhaust gas enter the packing layer through the packing. Dosing system to prevent acid and alkali waste gas. It has a neutralizing effect and is a common equipment for reducing the concentration of exhaust gas pretreatment.

Water spray tower activated carbon adsorption equipment

(2) Water spray tower + activated carbon adsorption equipment:

It is a different component, suitable for treating low-concentration exhaust gas. Particulate dust, fumes and grease can be removed by exhaust scrubbers. The treated waste gas is adsorbed by the activated carbon adsorption tower. The function of the exhaust gas scrubber is to purify the exhaust gas and prevent particulate matter from clogging the activated carbon adsorption tower, thereby reducing the adsorption efficiency.

.Low operating cost, waste gas washing tower, need to continuously add acid-base solution, and the washing tower will increase wind resistance, thereby increasing the power of the equipment, making the operating cost increase

Spray tower, water washing waste gas tower, washing tower, acid mist treatment tower

Spray tower, water washing waste gas tower, washing tower, acid mist treatment tower, its main function is to reduce the concentration of waste gas by washing, and through the dosing system, let the waste gas enter the packing layer, and neutralize the acid and alkali waste gas. Common equipment for pretreatment to reduce concentration. Cyclone tower is a kind of waste gas tower. Using the function of cyclone, it can make the desulfurization and deacidification more sufficient and play the role of desulfurization and deacidification.

Spray tower is a kind of waste gas treatment equipment, also called waste gas tower, acid mist tower, purification tower, washing tower, absorption tower, adsorption tower, acid mist spray tower and other names. The packing layer in the spray tower is used as a mass transfer device for the contact components between the gas and liquid phases. A packing support plate is installed at the bottom of the packed tower, and the packing is placed on the support plate in a random manner. A packing pressure plate is installed above the packing to prevent it from being blown by the updraft. The spray liquid of the spray tower is sprayed onto the packing from the top of the tower through the liquid distributor, and flows down along the surface of the packing. The gas is fed from the bottom of the tower, and after being distributed by the gas distribution device, it continuously passes through the open space of the packing layer in countercurrent to the liquid. So as to achieve the purpose of purifying the exhaust gas. The combined use of the spray tower and the activated carbon environmental protection box can well remove the organic waste gas in the waste gas of the spray booth.

Spray tower is a popular waste gas treatment equipment. Spray tower is also known as acid mist purification tower, absorption tower, acid gas scrubber, waste gas treatment tower, etc. The removal of harmful gases in the air is its strength.

Spray tower is a kind of waste gas treatment equipment often used in waste gas treatment process. Spray tower is also called waste gas treatment scrubber, acid mist scrubber, organic waste gas treatment scrubber, acid mist purification tower, acid gas purification tower, Acid mist absorption tower, exhaust gas purification tower and FRP acid mist purification tower can remove harmful gases in the air. It is often used to treat various organic waste gases such as electroplating waste gas, pickling hydrochloric acid waste gas, hydrogen sulfide waste gas, chlorine dioxide waste gas, coating workshop waste gas, and coating line waste gas.

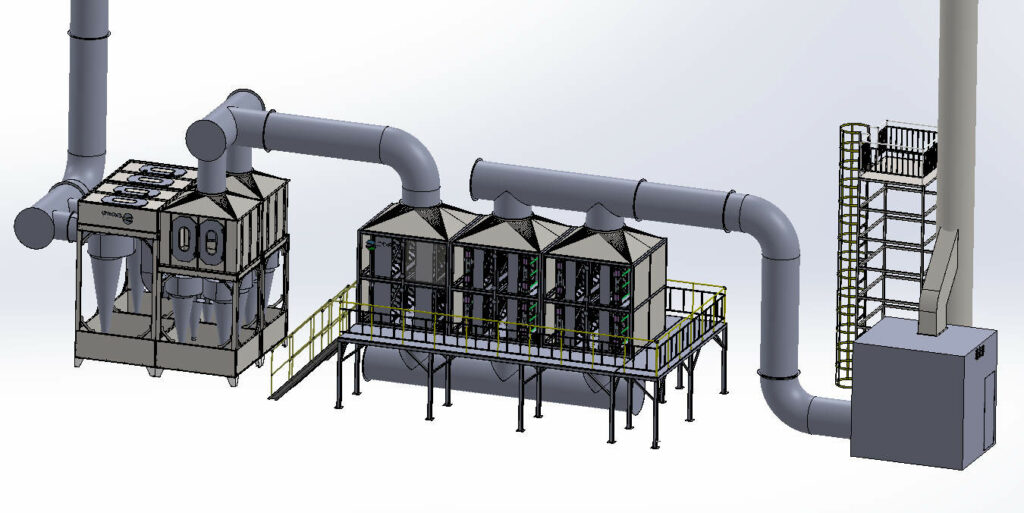

Paint mist scrubber waste gas treatment equipment

Paint mist scrubber waste gas treatment equipment

The adsorption tower exhaust gas treatment equipment is first passed. The paint mist washing tower adopts the working principle of the gas-liquid absorption method to perform preliminary adsorption treatment on the oily, particulate matter and part of the organic waste gas in the exhaust gas. The clean exhaust gas uses activated carbon particles to adsorb organic gases. It can prolong the life of activated carbon and reduce the possibility of activated carbon clogging.

The waste gas is collected by the pipeline and enters the new enzyme washing tower

After the waste gas is collected by the pipeline, it enters the new product enzyme washing tower for spray washing, which has certain physical dissolution and cover. After the waste gas is treated by the spray washing tower, the waste gas enters the photocatalyst (catalytic) oxidation filtration system, producing a large amount of high-energy ionic agent. The active group reacts chemically with the active free radical group in it, and is decomposed into harmless gas carbon dioxide and water. At present, this solution is not highly efficient, and can effectively remove pollutants such as dust, paint and additives such as phthalaldehyde. After treatment, it can be discharged up to the standard, the wind resistance of the exhaust gas treatment equipment is small, and the operation and maintenance cost is low.

Improve scrubber flowmeter issues

The old design method used the area flowmeter problem or called the floating straight

1. After using it for a long time, the scale cannot be seen clearly

2. It needs to be disassembled and cleaned every year

3. Cost of cleaning

4. Unable to calculate instant/monthly usage

General basic scrubber cleaning, scrubber maintenance and cleaning contents are:

◎Remove the window → ventilate

- Machine body scrubber cleaning

- Filled layer Raschig rings are cleaned and returned

- Remove the sprinkler head, clean it and put it back together

- All clear PVC cleaned

- water room cleaning

Work program

- Drain the wash cycle water inside the Scrubber and remove the Scrubber seal.

- Take out the Raschig ring and transport it to the designated location for cleaning.

- Clean the inside of the Scrubber with high-pressure water (including the sludge accumulated in the circulating water sprinkler head, air duct, liquid level window, etc.).

- Install the Scrubber side seal and place the cleaned Raschig ring in place.

- The sprinkler head is removed and cleaned to complete the installation.

- Install all Scrubber seals, all clear PVC locks to ensure no leaks, if anycrackedNotify the owner to replace.

- The above often needs to be replaced after a year or two due to the use of floating value flowmeters/area flowmeters

The following is a comparison of two flowmeters (floating value flowmeter/scraper cleaning electromagnetic flowmeter)

The following is a comparison of two flowmeters (floating value flowmeter/scraper cleaning electromagnetic flowmeter)

| cost | FMG-S scraper electromagnetic flowmeter | PFM float flowmeter |

| unit cost | NTD$80000 | NTD$20000 |

| construction cost | Same | |

| Durable cost | 5+ years | 2 years |

| maintenance cost | Low | high |

| Lifetime Conversion Rate | 90% | 30% |

| Feature | Instantaneous flow/cumulative flow | Instant flow |

| Digitization | Can | Can't |

| Cost after 5 years | NTD$80000 | NTD$100000 |

| win rate | win | fail |

| Product Image |  |  |

Design principle of scraper electromagnetic flowmeter

Scraper electrode electromagnetic flowmeter (scraper type) products are suitable for measuring conductive liquids, slurries, media that are easy to crystallize, scar, and easily contaminate electrodes in closed pipelines.Measurement accuracy and stability. The design and manufacture of the scraper electrode electromagnetic flowmeter (scraper type) conforms to the standard CE/IP67 "Electromagnetic Flowmeter". It is a velocity-type instrument for measuring the volume flow of conductive media. It can output standard current signals while performing on-site monitoring and display. , for recording, adjustment and control, to realize automatic control of detection and long-distance transmission of signals. Scraper electrode electromagnetic flowmeter (scraper type) Product features: ★There are no moving parts in the measuring tube, which is convenient for maintenance and management;loss;

★The conductivity of the tested liquid is ≥20μs/cm, and with various lining materials, it can be used to measure the flow of various acids, alkalis, salt solutions, and mud, pulp, pulp and other media;

★The measurement accuracy is not affected by changes in the density, viscosity, temperature, pressure and conductivity of the fluid. The sensor induced voltage signal is linear with the average flow rate, and the measurement accuracy is high;

★Low-frequency rectangular wave excitation, not affected by power frequency and various disturbances on site, and stable operation;

★Unaffected by the direction of the fluid, both forward and reverse can be accurately measured;

★ LCD backlight display, parameters can be modified online, easy to operate;

★Chinese and English display modes (optional);

★Can record forward total, reverse total and difference total;

★It has the functions of empty pipe measurement and alarm, and can adapt to different fluid media.

Main technical indicators of scraper electrode electromagnetic flowmeter (scraper type) products:

■ Applicable measuring diameter: dn80mm~dn1600mm

■ Dielectric conductivity: ≥20 μs/cm

■ Lining material: polychloroprene, polyurethane, polysilicon, ptfe, f46, pfa

■ Electrode material: sus316, Hastelloy b (hb), Hastelloy c (hc), titanium (ti), tantalum (ta), platinum/iridium alloy

■ Working environment temperature: -20℃~60℃

■ Converter working environment humidity: ≤95%

■ Shell protection grade: ip65, ip67, ip68

■ Velocity measurement range: 0.5 to 10 m/s

■ Matching accuracy grade: 0.5, 0.2

■ Measurement parameters: instantaneous flow rate, flow rate, cumulative total of forward and reverse

■ Detection alarm parameters: fluid empty pipe detection alarm, excitation current detection alarm, upper and lower limit alarm, system alarm

■ Network function: hart, modbus, gprs, profibus (optional)

■ Power supply

AC power supply, voltage range: 85vac ~ 250vac DC 24v power supply, voltage range: 20vdc ~ 36vdc self-powered 3.6v power supply

Head motor water pump:Special design lining for vertical pipes/ Electromagnetic Flowmeter Technology

General flowmeters are applicable when the design is adoptedHorizontal pipe installation, But most of the protective lining is made of rubber material, because the rubber lining material is easy to be deformed by the water sag effect of the lift motor pump, because this kind of deformation can easily damage the sealing structure of the electrode sensor in the original electromagnetic flowmeter. Therefore, many instrument factories simply use high-grade PTFE materials, but many instrument factories lack the correct concept of educating agents. After all, this is called lining under petrochemical products, and each lining has its own characteristic table. In this case, PTFE cannot be used. Such materials require the use of polytetrafluoroethylene modified materials

PTFE products also have excellent sliding characteristics, excellent electrical resistance and non-bonding surface. Because of the sliding characteristics, it also leads to the selection of high unit cost in the production of electromagnetic flowmeter electrode sealing technology, but does not reach the actual anti-lift. The function of motor negative pressure sag effect

After years of engineering practice experience, FGT Flowmeter Instrument Factory has developed durable electromagnetic flowmeters for vertical pipe installation, and is also applied to grouting in the cement industry.