FGT think your best choice in the future

System Integration Designers in FGT

- 2022-03-24

- 2:50 pm

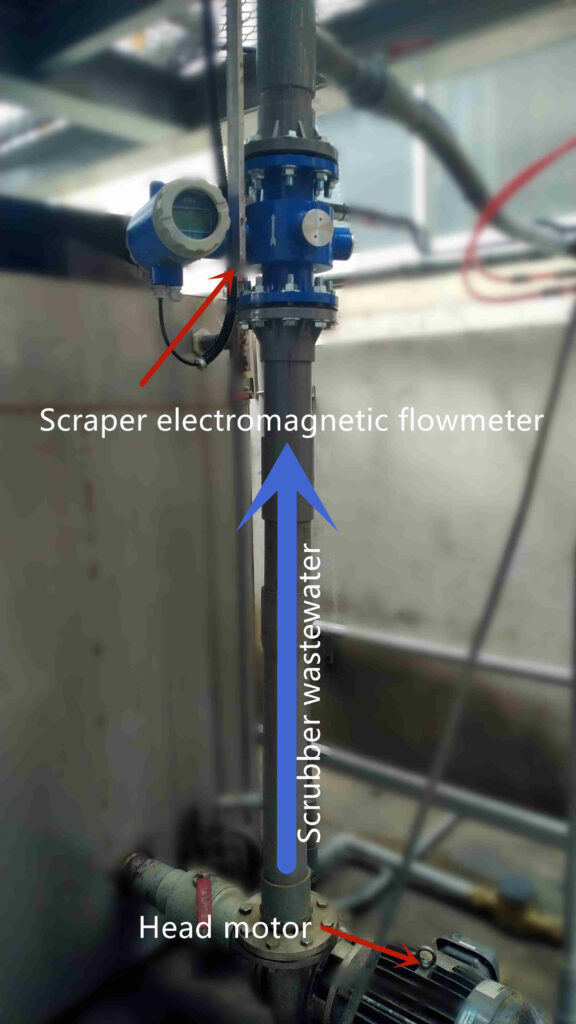

Scrubber head motor | Vertical pipe electromagnetic flowmeter | Design considerations

Head motor|

Vertical Pipe Mount Flowmeter Design

Many times when designing vertical pipes, designers often encounter the standard installation requirements for electromagnetic flowmeters: horizontal installation, this project uses vertical pipes, and under space constraints, electromagnetic flowmeters need to be installed on the lift motor. Modified electromagnetic flowmeter enhanced accessories to discuss.

Before Design | Pipeline Wastewater Composition

First of all, many designers did not clarify the following conditions for the use of water when designing the head motor.

1. Water pH: acid water/alkaline water

2. Water temperature: normal temperature/high temperature/low temperature

3. Water quality components: waste water/oily mixed water/pure water/tap water.

Before Design |

The head motor pipe is equipped with a flowmeter

At the motor water outlet: 10D or 20D is the standard distance for using a flowmeter to become a head motor. Why are many designs requiring this?

Reason: When the water passes through the water outlet of the head motor, the flow rate and flow rate at this time have not reached a certain pipe pressure stability, and the water inside will be very large and small, and then when the head motor starts, the water pressure It is very large that the water flows upward through the head motor. At this time, the pipe pressure is very large, but the flow rate is not high. Besides, the distance of the flow meter is too close to the head motor.

Wrong design | The flowmeter distance is too close to the head motor problem

The electromagnetic flowmeter itself has a contact-type electrode sensor. When the distance between the lift motor and the flowmeter is too close, as long as the flowmeter is used to measure the water flow rate directly through the sensor, the pipe pressure is too high or uncertain. When the flow rate is high and low, it is easy to damage the sensor of the electromagnetic flowmeter itself.

Therefore, many technical manuals when using flowmeters will say that the distance from the previous node equipment must be 10D or 20D.

Correct selection of lining protection | lining selection of electromagnetic flowmeter

PTFE or PFA are stupidly unclear: many times it does not mean that PFA is the best lining material

It is especially used when the pipeline itself has backflow water. At this time, F46 in PTFE is the best material.

For the selection of F46 for electromagnetic flowmeters, please refer to the following general description, which will not be discussed separately.

Regarding the "electric diaphragm pump" tag, the search engine has related information discussions

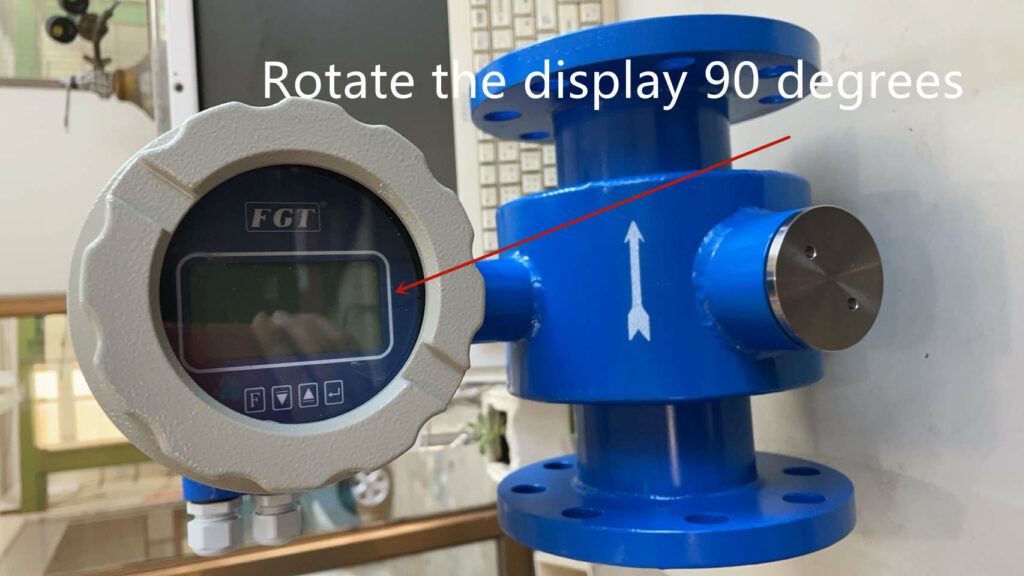

Pay attention to the electromagnetic flowmeter installed in the vertical pipe of the lift motor

- flowBody Orientation

- There is an arrow on the flange body of the electromagnetic flowmeter, please install it correctly according to the direction of water flow

- Exclusive 488 protocol method, exclusive network router settings, to avoid conflicts with the WIFI system of the residents

- display position

- The display, such as FGT's FMG series electromagnetic flowmeter, is designed to change the direction of the display by rotating 360 degrees or 90 degrees.

What are the functions of the scraper electromagnetic flowmeter?

When the electromagnetic flowmeter measures the medium with serious pollutants, after long-term operation, a layer of non-conductive dirt will form on the electrode surface of the flowmeter, which will affect the electrode signal in the long run. In this case, the scraper electromagnetic flowmeter can fully played its role.

After using the scraper electromagnetic flowmeter, the scraper electrode can remove the dirt on the electrode. The specific method is as follows: open the cover, turn the knob, and turn the scraper to scrape the dirt on the surface of the electrode. It can be cleaned during the operation of the electromagnetic flowmeter. After cleaning, the direction of the scraper is rotated to the direction of fluid flow (there is a direction mark on the knob)

The scraper electromagnetic flowmeter has the following functions:

1. Power outage record function: You can check the malicious outage record at any time to prevent the electromagnetic flowmeter from not measuring or measuring less. (optional)

2. Lightning strike protection function: prevent irreparable damage to the electromagnetic flowmeter caused by lightning strikes.

3. Computer data collection function: When the flowmeter is installed far away and it is inconvenient to read the meter, the function of updating the flow data collected by the computer every 5 seconds plays an important role. (optional)

4. Electrode self-checking function: The electrode is the key component of the electromagnetic flowmeter. The pollution of the electrode will affect the flow measurement. The self-checking function can prevent the influence of pollution in time.

5. The circuit part generates lower heat: the electromagnetic flowmeter is installed in the outdoor field. The high temperature in summer and the high heat generated by itself will cause many electromagnetic flowmeters to burn out, but in the case of lower heat generation, it can be very good. Avoid this from happening.

What is a wet scrubber

Traditional scrubbers are capable of removing tiny particles, but the problem is that they consume too much energy, which is much higher than the power required by an electrostatic precipitator or fabric filter. Wet washing has a wide range of applications, and there are more options than fabric filters or electrostatic precipitators, which is a unique feature. The scrubber can handle high temperature gas. It removes both gaseous pollutants and solid particles, and also reduces the possibility of fires and explosions. Therefore, a lot of research and improvements have been made on it to reduce the energy consumption when dealing with tiny particles. These improvements can be mainly divided into the following aspects: 1. Improvement of traditional washing technology; 2. Steam-assisted washer; 3. Electrostatically increased washer; 4. Fiber media washer; 5. Foam washer.

3-minutes to understand the pumping principle, form classification, selection method

The principle of submerged pumping

Submersible pumping seems to be more complicated, but in fact, the principles behind it are similar. The pressure chamber of the submersible pump is actually composed of an array of blades similar to the centrifugal pump. After the liquid is continuously rotated and pressurized by multiple groups of blades, the liquid passes through the slow-closing check valve (Non- Slam Check Valve) to reduce water hammer effect. Therefore, the achievable pressure of submerged pumps is often higher than that of onshore pumps. In addition, submersible pumps are particularly suitable for treating sewage or high viscosity liquids because there are no narrow channels in the design.

The following is an introduction video of the principle of submerged water pumping. You can see how the submerged water pump pressurizes the liquid. Those who are interested can watch it (you can turn on the subtitle translation function if you do not understand English!) The video understands submerged water pumping how it works

Weak current engineering, weak current industry, weak current system, weak current intelligence, weak current safety monitoring, intelligent weak current, weak current integration, weak current general contractor, weak current integrator, weak current manufacturer, weak current wiring, weak current cable, household weak current box, weak current sales, weak current engineer , weak current designer, weak current chief engineer, weak current engineering manager, weak current industry, weak current maintenance, weak current construction team, etc., weak current engineering company, weak current engineering Taipei weak current engineering license, weak current engineering work content, weak current engineering English.