FGT think your best choice in the future

System Integration Designers in FGT

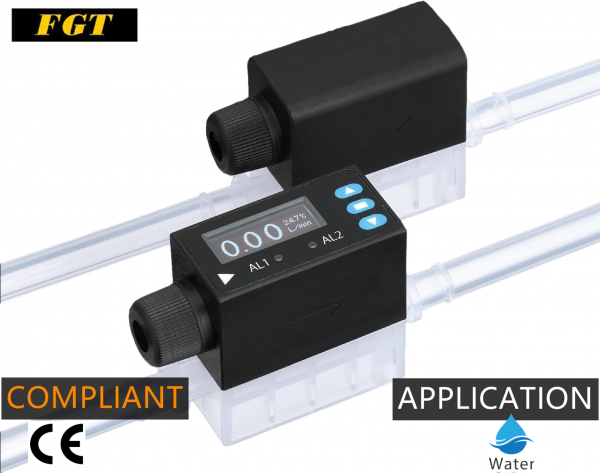

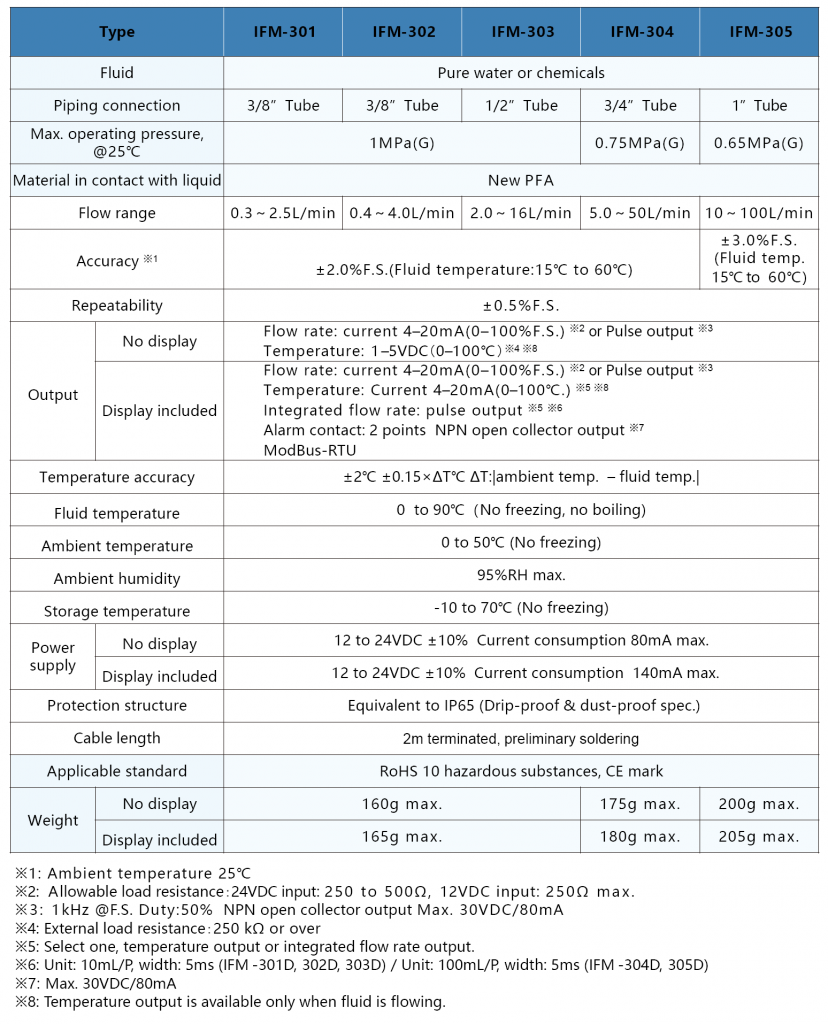

IFM300 type: Karman vortex flowmeter | kofloc brand

The IFM300 series Karman vortex flowmeter from Japan's kofloc manufacturer | is an ideal tool for measuring and monitoring liquid flow (including cooling water and clean water). All models in this series offer outstanding reliability and durability thanks to the addition of temperature measurement and PFA resin for corrosion-resistant materials. ■ Applicable fluids: liquid water, pure water, chemicals

■ Maximum flow: liquid 2.5 – 100L/min

■ Accuracy: ±2 to 3% FS

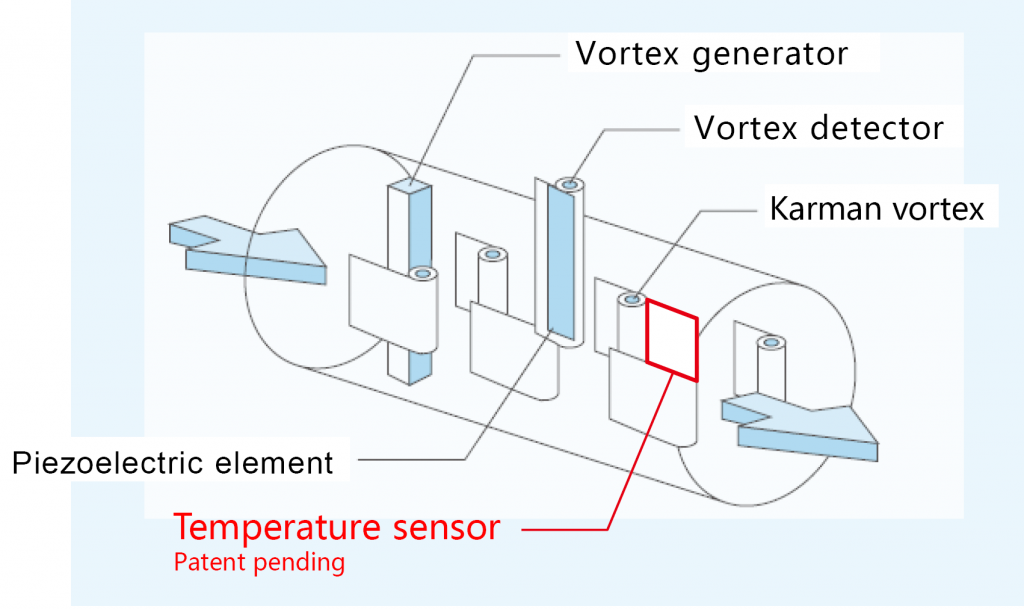

■ Equipped with a temperature sensor to measure the fluid temperature, temperature correction reduces the accuracy error caused by the fluid temperature change.

■New PFA for wetted parts (no O-ring)

■Compact design

■Support a wide flow range (from 0.3 to 2.5 L/min to 10 to 100 L/min)

■Waterproof equivalent to IP65

- Description

- Additional information

- Technical Specifications

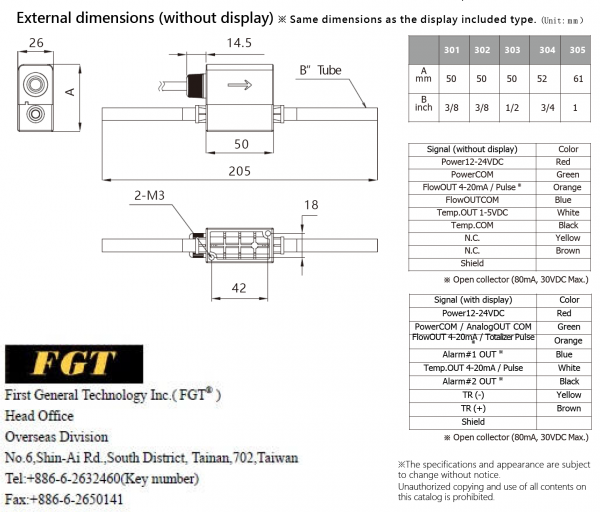

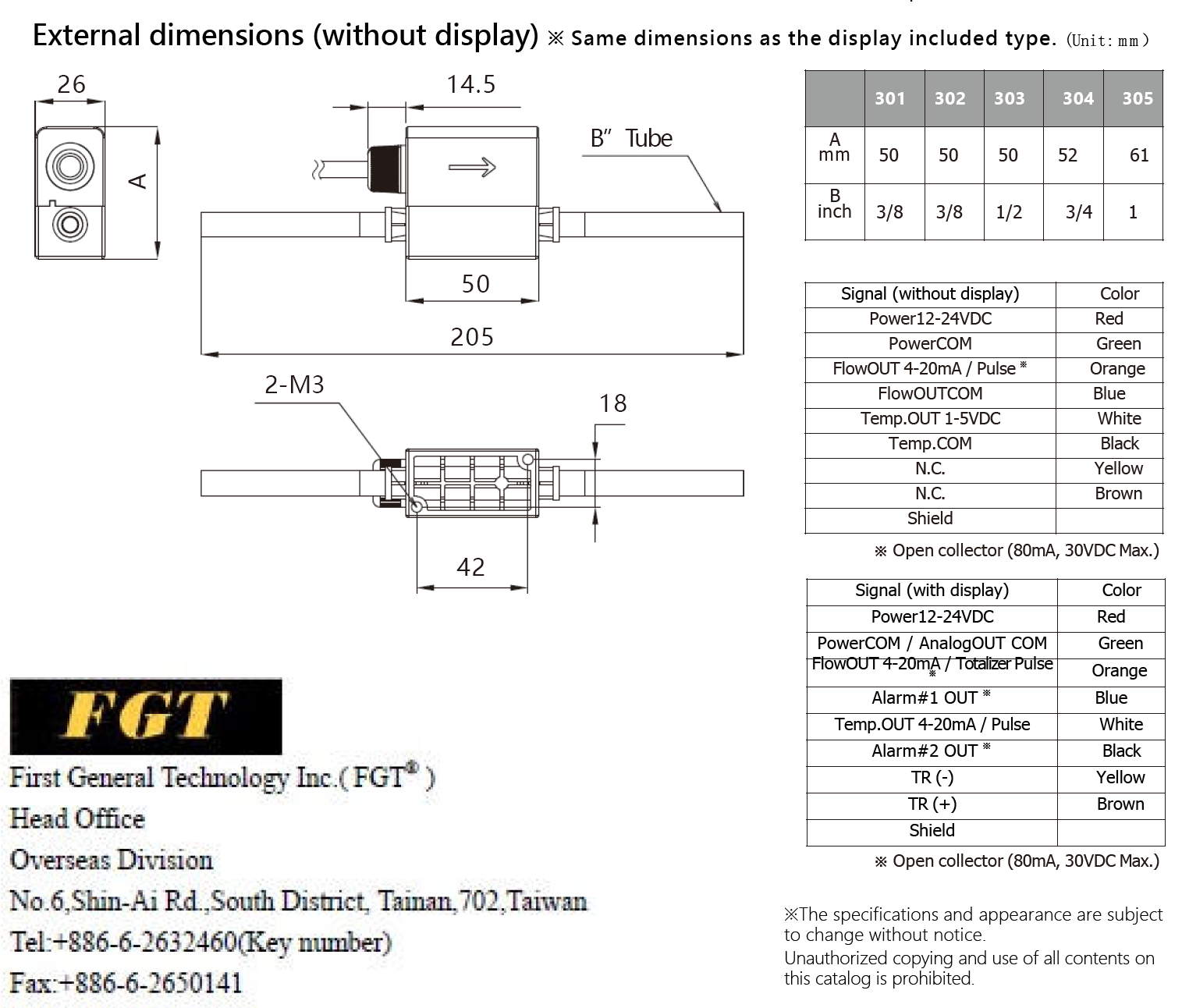

- Dimensions

- Application

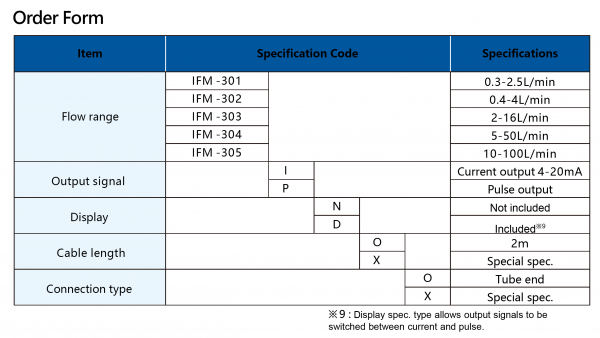

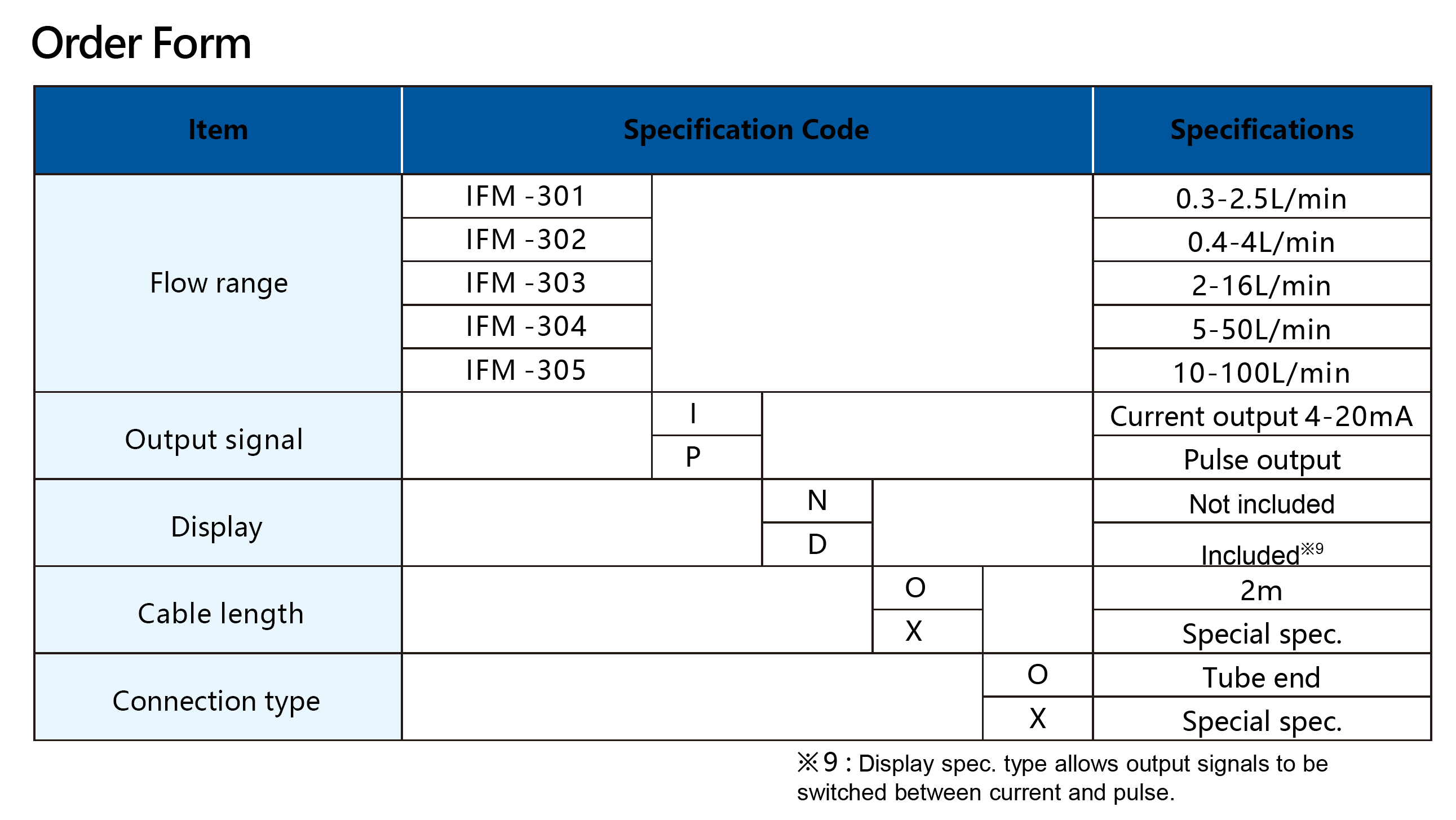

- Ordering Information

- certified

- Special needs

- Inquire now

kofloc brand IFM300 vortex flowmeter characteristics

■ Applicable fluid: liquid water, pure water, chemicals

■ Maximum flow: liquid 2.5 – 100L/min

■ Accuracy: ±2 to 3% FS

■ Equipped with a temperature sensor to measure the fluid temperature, temperature correction reduces the accuracy error caused by the fluid temperature change.

■New PFA for wetted parts (no O-ring)

■Compact design

■Support a wide flow range (from 0.3 to 2.5 L/min to 10 to 100 L/min)

■Waterproof equivalent to IP65

IFM300 flowmeter characteristic technical introduction

Vortex flowmeter principle

This device is a vortex flowmeter that utilizes a law theoretically proved by Theodore von Karman in 1912. Alternating vortices are generated downstream in the presence of cylindrical obstacles (vortex generators) in the flowing fluid.

The flow velocity of the fluid is proportional to the swirl frequency. Therefore, detecting the number of vortex pulses can measure the flow rate. The main detection method is to use piezoelectric elements to sense eddy current vibrations. But using ultrasound to detect eddy current vibrations is more reliable.

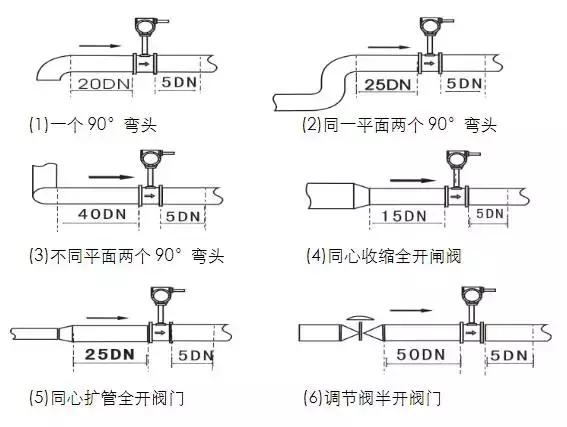

Vortex flowmeter installation

The main installation requirement of the vortex flowmeter is the requirement for the straight pipe section. The upstream and downstream sides of the vortex flow sensor should have a long straight pipe section.

For vortex flowmeters, when measuring fluid flow, if the measured fluid only contains a small amount of liquid, the flowmeter should be installed at a higher point in the pipeline.

When measuring liquid, if the measured liquid contains a small amount of fluid, the flowmeter should be installed at the lower part of the pipeline.

Vortex Flowmeter Disadvantages

- Since it restricts the flow path, pressure loss occurs

- Scale and liquids containing solids can cause clogging

- Not suitable for high viscosity fluids

- Sensitive to pipeline vibration

- need a piece of straight pipe

- Bubble effect: When the liquid flows in from the inlet, air may also be mixed into it, together with the impurities mixed into the liquid to form bubbles, which will accumulate due to temperature changes. In a vortex flowmeter, air bubbles interfere with the formation of the Karman vortex, while in an ultrasonic flowmeter, the propagation of ultrasonic waves is suppressed, causing failure or false readings.

- Mud effect: Mud is a general term for liquids containing a certain amount of homogeneous solid particles, including liquids containing abrasives. Individual particles may cause wear inside the flowmeter, or they may agglomerate and clog.

- Non-uniform flow velocity distribution: After the fluid flows through a long enough straight pipe, the distribution of the flow velocity in the circular pipe will be stable. On the other hand, bending pipes or changing pipe diameters can lead to unstable flow velocity distribution. There are two types of unstable flow velocity distributions: bias flow, where the center of the flow velocity distribution deviates from the center of the pipeline; swirl flow, where the fluid flows while rotating along an axis parallel to the flow direction. Flow measurement in this state may lead to large measurement errors.

- Ripple: When the ripple is large, the instantaneous flow may exceed the rated flow of the flowmeter in an instant. At this time, the flow rate displayed by the flowmeter is less than the actual flow rate through the pipeline. Positive displacement reciprocating pumps are prone to large ripples.

- Pipeline vibration: When the fluid flows through the pipeline or the valve opens and closes, the pipeline itself will vibrate. In addition, the vibration generated during the operation of equipment and devices may also be transmitted to the pipeline.

Advantages of vortex flowmeter

- no mechanical moving parts

- Can detect liquids, gases and vapors

- Excellent chemical resistance due to the absence of electrodes

- Large measuring range and high precision

pressure flow meter

| Control | AI, BI, DDC, IOT, MCU, PLC |

|---|---|

| Application | Flow Meter |

| Types of | mechanical, electronic |

| Installation method | flange, insert |

| Output method | Analogy signal |

Application

■ Applicable fluid: liquid water, pure water, chemicals

Used for flow control of various cooling water, chillers, temperature control, molds, industrial heating furnaces, vacuum heat treatment furnaces, application quenching equipment, experimental high temperature furnaces, etc.

■ Maximum flow: liquid 2.5 – 100L/min

■ Accuracy: ±2 to 3% FS

Equipped with a temperature sensor to measure the fluid temperature, temperature correction reduces the accuracy error caused by the fluid temperature change.

Wetted parts new PFA (no O-rings)

compact design

Supports a wide flow range (from 0.3 to 2.5 L/min to 10 to 100 L/min)

Waterproof grade equivalent to IP65

certified