FGT think your best choice in the future

System Integration Designers in FGT

The installation and use of the flowmeter must pay attention to these matters!

The installation and use of the flowmeter must pay attention to these matters!

Install

FlowmeterIt is an indispensable instrument for measuring the flow of liquid and gas. I believe everyone has seen many different types of flow meters. The correct installation method is very important for the flow meter. Today, the editor brings you several common installation requirements for flow meters, hoping to be helpful to everyone.

Correct installation design

Electromagnetic Flowmeter

In order to make the electromagnetic flowmeter work stably and reliably, ferromagnetic objects and equipment with strong electromagnetic fields should be avoided as far as possible when choosing the installation site, so as to avoid the magnetic field affecting the working magnetic field and flow signal of the sensor.

The measurement principle of the electromagnetic flowmeter does not depend on the characteristics of the flow. If there is a certain turbulent flow and vortex in the pipeline, it has nothing to do with the measurement. If there is a steady eddy current in the measurement area, it will affect the stability and accuracy of the measurement. At this time, you can increase the length of the front and rear straight pipe sections, use a flow stabilizer, or reduce the cross section of the measurement point to stabilize the flow velocity distribution.

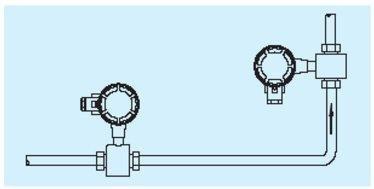

The flowmeter can be installed horizontally and vertically, but it should be ensured to avoid the influence of deposits and air bubbles on the measuring electrode, and the electrode axis should be kept horizontal. When installed vertically, the fluid should flow from bottom to top.

Horizontal and vertical installation

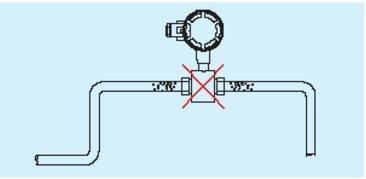

The flowmeter cannot be installed in the highest position of the pipeline, which is prone to accumulation of air bubbles.

The flowmeter cannot be installed in the highest position of the pipeline

Make sure that when the flowmeter is measuring, the pipe is full of the fluid to be measured, and the pipe cannot be partially full. If the pipeline is not full or the outlet is empty, the flowmeter should be installed on a siphon.

Installation between elbows, valves and pumps

Vortex flowmeter

The main installation requirements of the vortex flowmeter are the requirements for straight pipe sections. There should be long straight pipe sections on the upstream and downstream sides of the vortex flowmeter.

For the vortex flowmeter, when measuring the gas flow, if the measured gas contains a small amount of liquid, the flowmeter should be installed at a higher part of the pipeline. When measuring liquid, if the measured liquid contains a small amount of gas, the flowmeter should be installed at the lower part of the pipeline.

Ultrasonic flowmeter

Ultrasonic flowmeter is also a relatively common flowmeter. Its installation is the most simple and convenient in all flowmeter installations. Just select a suitable measurement point, input the pipeline parameters at the measurement point into the flowmeter, and then put The probe can be fixed on the pipe.

The installation of ultrasonic flowmeter mainly follows the following points:

1. Choose a pipe section filled with fluid that is uniform and dense, and easy to transmit ultrasonic waves, such as a vertical pipe section or a horizontal pipe section.

2. The installation distance should be a straight pipe section with no valves, elbows, variable diameters, etc. within the upstream diameter greater than 10 times the straight pipe diameter and downstream greater than 5 times the straight pipe diameter. The installation point should be sufficiently far away from valves, pumps, high-voltage electricity and Inverter and other interference sources.

3. Avoid installation on the highest point of the piping system or vertical pipes with free exits.

4. For open or half-filled pipes, the flowmeter should be installed at the U-shaped pipe section.

Its installation requirements are as follows:

1. The installation position of the flowmeter should be as far as possible to choose a straight pipe section with a straight pipe diameter greater than 10 times the straight pipe diameter upstream and 5 times the straight pipe diameter downstream without any valves, elbows, variable diameters, etc. This installation condition will help ensure that Has a more symmetrical velocity profile;

2. In order to eliminate the adverse effects of condensed water in the biogas pipeline, it is recommended that users install a blowdown valve before the straight pipe section, and properly raise the installation position of the flowmeter, so that the condensed water can be effectively discharged at the front blowdown outlet;

3. A bypass pipe section is connected in parallel next to the pipeline of the biogas flowmeter to facilitate the maintenance of the flowmeter. The pipeline at the inlet of the biogas flowmeter must be fitted with a valve that closes the gas path. After the biogas flowmeter is installed, the tightness of the connection should be checked;

4. It is strictly forbidden to use open flame for leak detection. The gas pressure entering the biogas flowmeter shall not exceed its specified maximum pressure value;

5. The inner diameter of the flow meter body should be consistent with the inner diameter of the straight pipe section, which is especially important for the straight pipe section upstream of the flow meter;

6. The misalignment of the axis between the flow meter body and the connected straight pipe section is minimized, and the biogas flow meter should ensure that the gas chamber is installed horizontally;

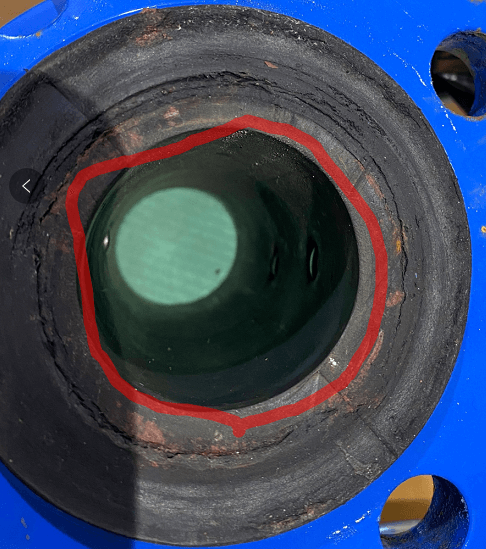

7. Gaskets such as protruding into the pipeline may cause disturbance to the flow field distribution. Measures should be taken to ensure that the gasket is on the flange sealing surface and is concentric with the flange, and no gasket is allowed to protrude into the pipeline;

8. During installation, check whether the inner cavity of the measuring pipe section of the flowmeter is clean. If there is grease and dust, it should be cleaned in time.

Through the introduction of the above flowmeters, the installation methods of flowmeters under common working conditions are relatively clear. For the installation of flowmeters under complex working conditions, specific analysis is required. Accumulating rich experience is the most important part of solving problems. .

wrong installation

1. Because the weight of the flowmeter itself is not considered, the inner lining will be damaged by pressure due to excessive pressure.

2. Install the flowmeter: wrong design on the piping

- The valve body design should be placed in front of the flow meter

- There is no design 10D at the 90-degree elbow and 5D behind