FGT think your best choice in the future

System Integration Designers in FGT

Display type mass flow meter/mass flow controller 8700 series | kofloc brand

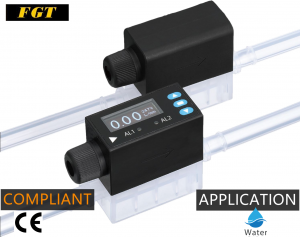

The Japanese kofloc manufacturer complies with SEMI and CE certification | The 8700 series is a display type mass flow meter/mass flow controller developed based on the 8500 series. Applicable gases: N2, Air, H2, He, Ar, O2, CO2, etc. Flow range: 10SCCM ~ 100SLM with display screen, easy to operate.・Real-time cumulative flow indication.・Upper limit or lower limit alarm setting. RS485 communication. 0-5VDC input/output signal (4-20mA switchable

- Description

- Additional information

- Product Dimensions

- Product Manual

- Communication Development Manual

- certified

- Special needs

- Inquire now

kofloc brand display mass flow meter/mass flow controller 8700 series

The 8700 series is a display mass flow meter/mass flow controller developed based on the 8500 series. It has been developed as a standard model for various mixed gas analyzers and vacuum equipment, and is used for the development of vacuum equipment and battery flame mixing equipment.

feature

・Display: integrated type and separate type

・Can be mounted on the surface of the control panel

Standard Specifications

- Applicable gases: N2, Air, H2, He, Ar, O2, CO2, etc.

- Flow range: 10SCCM~100SLM

- Accuracy: ±1~1.5%F.S.

- Various flow ranges from FS10SCCM to FS100SLM are available via N2 conversion.

- With display screen, easy to operate.

・Instant cumulative flow indication.

・Upper limit or lower limit alarm setting. - RS485 communication.

- 0-5VDC input/output signal (4-20mA switchable).

Application field

・Air sampling

・Analyzer parts

·Bioreactor

・Biotechnology process

・Combustion control

・Made in CCFL

・Room pressure control

・Chemical process

・Environmental monitoring

・Manufacture of electronic equipment

・Food production

・Fuel cell test

・Fermentation process

・Gas mixing

・Gas distribution

・Airflow monitoring

·Gas generation

·Industrial furnace

·Leak detection

·Pharmaceutical process

·Pollution monitoring

·Process control

·R&D

·Solar cell manufacturing

· Secondary calibration reference

・Semiconductor process

・Surface treatment process

・Thermal flame spraying

・Film manufacturing

・Vapor deposition

Mass Flow Controller Applications

- Plasma Cleaner

- Gas diverter valve box/panel

- Gas cylinder cabinet output flow control

- Gas generator output control

- flame welding control

What types of mass flow controllers exist for the 8700 series?

Thermal mass flow controllers use the thermal mass sensing technique of gases to control their mass flow. In the TMFC portfolio we have several thermal mass flow controllers, each with its own sensor technology:

Mass flow controllers using bypass sensors. These devices, such as TMFCs and TMFMs, are ideal for clean and dry gas applications where greater precision and repeatability are required.

Mass flow controller using the on-line principle. Series such as the TMFC and TMFM series are perfect if your application has high purity gases above 99.9%, or when high repeatability and robustness are more important than accuracy.

Gas mass flow controller using piping control technology. These series stand out because they can measure gas flow and control.

Whenever your mass flow needs to be displayed and over a wide flow range, a gas series using MEMS chip sensor technology such as the TMFM6000 is perfect.

Gas mass flow controllers using in-line (CMOS) technology.

Mass Flow Controller ( MFC ) Principle / Flow Controller Principle

A mass flow controller (MFC) is a device used to measure and control the flow of liquids and gases. [1] Mass flow controllers are designed and calibrated to control a specific type of liquid or gas over a specific flow range. The MFC can have a set point between 0% and 100% of its full scale range, but typically operates within the full scale range of 10% to 90% for best accuracy. The device will then control the flow rate to the given set point. MFCs can be analog or digital. Digital flow controllers are usually capable of controlling more than one fluid, while analog controllers are limited to the fluids they are calibrated for.

All mass flow controllers have an inlet port, an outlet port, a mass flow sensor, and a proportional control valve. The MFC is equipped with a closed loop control system where the operator (or external circuit/computer) provides an input signal which is compared with the value of the mass flow sensor and adjusts the proportional valve accordingly to achieve the desired flow. Flow is specified as a percentage of its calibrated full scale flow and is provided to the MFC as a voltage signal.

Mass flow controllers require the supply gas or liquid to be within a specific pressure range. Low pressure will deplete the MFC of fluid and prevent it from reaching its set point. High pressures may cause erratic flow rates. There are many different technologies that help measure the flow of fluids and ultimately help control flow. These technologies define the types of mass flow controllers and they include differential pressure (ΔP), differential temperature (ΔT), Coriolis force, ultrasonic, electromagnetic, turbine, etc.

Mass Flow Meter Installation

Now there are more and more applications of mass flowmeters, and some occasions where mass flowmeters are installed for the first time are not clear about the installation method of mass flowmeters, reverse installation, wrong installation, etc., which affect the normal use of the equipment. This article discusses this problem Describe in detail how to install a mass flow meter.

Excessive mechanical stress during sensor installation will affect the zero point of the mass flowmeter. If these stresses are constantly changing, the zero point drift of the meter will cause inaccurate measurement and cannot work normally. Therefore, the correct installation of the mass flowmeter is an important part of ensuring the normal operation of the equipment.

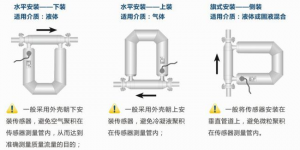

1. Choose the installation method

The installation method of the sensor is mainly determined according to the phase difference of the fluid and its process conditions. There are three installation methods.

1. If the measured fluid is a liquid, the sensor is generally installed with the shell facing down to avoid air accumulation in the vibrating tube of the sensor, so as to achieve the purpose of accurately measuring the mass flow rate.

2. If the measured fluid is gas, the sensor is generally installed with the shell facing upwards to avoid accumulation of condensate in the sensor vibration tube.

3. If the measured fluid is a mixed slurry of liquid and solid, install the sensor on a vertical official road, which can prevent particles from accumulating in the sensor's Coriolis force measuring tube. In addition, if the process pipeline needs to be cleaned with gas and steam, this installation method can also facilitate cleaning, but this installation method is more difficult to fix than the previous two, and the pressure loss is larger.

gas flow controller

gas mass flow controllers

Mass Flow Formula

Types of mass flow meters

mass flow meter english

according toThree degrees Chinese website.Multiple interpretations mass flowmeter【electronic computer term】mass flow meter【mechanical engineering】mass flowmeter sensor【marine science term-underwater engineering】thermal mass flow【electronic engineering】mass flow measurement【electrical engineering】

What is the use of electromagnetic flowmeter? | Our performance

What is a mass flow meter used for? | Our performance

What is the use of vortex flowmeter? | Our performance

What is the use of ultrasonic flowmeter? | Our performance

What is a gear flow meter used for? | Our performance

What is a float flow meter used for? | Our performance

| Application | Flow Meter |

|---|---|

| Types of | Electronic |

| Installation method | Thread |

| Output method | digital, analog |

Product Dimensions

FGT authorized Taiwanese sellers for kofloc (more than 10 years of cooperation experience between the two parties)

The certified warranty sticker has been verified by the FGT secondary quality inspection label

Product Manual

FGT authorized Taiwanese sellers for kofloc (more than 10 years of cooperation experience between the two parties)

The certified warranty sticker has been verified by the FGT secondary quality inspection label

Communication Development Manual

Communication Development Manual Download

FGT authorized Taiwanese sellers for kofloc (more than 10 years of cooperation experience between the two parties)

The certified warranty sticker has been verified by the FGT secondary quality inspection label

certified