FGT think your best choice in the future

System Integration Designers in FGT

Product Features

- Pressure range: positive pressure 0~1MPa

- Pressure resistance: 0~1MPa

- High precision and resolution.

- low cost

Application method

- Industrial equipment piping pressure

- Check line pressure

- Vacuum pad pressure

Applicable fluid

- Air

- No corrosive gas

- non-flammable gas

Supply voltage

- DC12~24V

Connection size

- F1: 1/8″PT

- F2: 1/8″NPT

- F3: 1/8″G

Line length type

- straight out

- Quick plug outlet

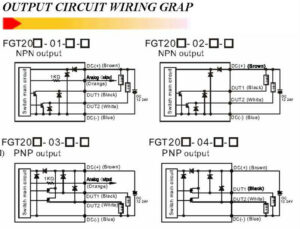

- 2NPN output + 1 analog output

- 2NPN

- 2PNP output + 1 analog output

- 2PNP

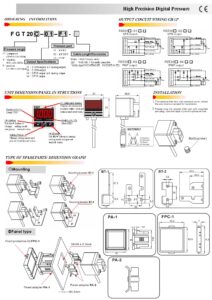

optional accessories

- Fixing frame (BT-1+BT-2)

- Panel Adapter (PA-1+PA-2)

- Panel Adapter + Front Protective Cover (PA-1+PA-2+FPC-1)

pressure transmitter[edit]

digital air pressure transmitter

pressure transmitteris used to measureliquidandgasofpressureofteleporter. Similar to other sensors, the pressure transmitter converts the pressure into an electrical signal output when it works.

Pressure transmitters are used extensively in many monitoring and control applications. In addition to direct pressure measurement, pressure transmitters can also be used to indirectly measure other quantities, such as liquid/gas flow, velocity, water level orAltitude.

Pressure transmitters vary greatly in technology, design, performance, working conditions and prices. It is roughly estimated that there are more than 60 kinds of pressure sensors and at least 300 enterprises producing pressure transmitters in the world.

At the same time, there is also a class of pressure transmitters designed to dynamically measure high-speed changing pressures. Example applications are the combustion pressure of an engine cylinder orTurbine enginePressure monitoring of gases in Such transmitters are generallyPiezoelectric materialmanufacture, for examplequartz.

Some pressure transmitters, such as those used in traffic enforcement cameras, operate in binary mode, that is, when the pressure reaches a certain value, the transmitter controls to turn on or off the circuit. This type of pressure transmitter is also called doPressure Switch.

Type of pressure measurement[edit]

Pressure transmitters can be classified by the pressure range they can measure, the operating temperature, and the type of pressure; the most important of which is the type of pressure. If classified according to the type of pressure, pressure sensors can be divided into the following five categories:

- Absolute pressure transmitter:

- This pressure transmitter measures the true pressure of the fluid, which is relative tovacuumpressure under pressure. The absolute atmospheric pressure at sea level is 101.325kPa (14.7 PSI).

- Gauge pressure sensor:

- This pressure transmitter can measure the pressure relative to atmospheric pressure at a specific location,tire pressure gaugeAs an example, when the tire pressure gauge shows a reading of 0PSI, it means that the pressure inside the tire is equal to the atmospheric pressure, which is 14.7PSI.

- Vacuum pressure transmitter:

- This pressure transmitter is used to measure pressures less than one atmosphere. Some vacuum pressure sensors in the industry read relative to one atmosphere (negative readings), while others are based on absolute pressure.

- Differential Pressure Gauge:

- This instrument is used to measure the pressure difference between two pressures, such as measuringoil filterThe pressure difference between the two ends, the differential pressure gauge is also used to measure the flow or measure the liquid level in the pressure vessel.

- Sealed pressure transmitter:

- This instrument is similar to a gauge pressure sensor, but it is specially calibrated to measure pressure relative to sea level.

Power Requirements[edit]

Constant current source and constant pressure source are two kinds of excitation commonly used by pressure transmitters. The two incentive methods are different and have different effects. Constant current source excitation is beneficial to the compensation of thermal sensitivity drift. Because the temperature coefficient of the bridge arm resistor is positive, and the sensitivity temperature coefficient is negative. The temperature coefficient of the output signal voltage under constant current excitation is the algebraic sum of the two. The constant voltage excitation cannot directly provide the effect of sensitivity temperature compensation. However, a thermistor or diode can be connected in series outside the bridge to compensate for thermal sensitivity drift when using a constant voltage source. With cross-current excitation, this sensitivity compensation method does not work. It can be seen that the excitation of the constant voltage source and the constant current source cannot be interchanged at will.

In addition, the excitation power supply of the pressure sensor can be divided into proportional excitation and fixed excitation. The former is to connect the pressure sensor bridge directly to the power supply. When the power supply changes, the sensitivity and zero point of the pressure sensor change accordingly. The latter has a reference voltage inside, and the pressure sensor bridge is powered and excited by the reference voltage. The reference voltage is constant regardless of the power supply. As long as the supply voltage varies within a specified voltage range, the reference voltage does not change. Therefore, the output of the sensor remains unchanged and is not affected by the power supply voltage.

pressure detection technology[edit]

| This chapter requiresexpansion. (July 26, 2010) |

Application[edit]

Pressure transmitters have the following applications:

- pressure measurement

- Altitude awareness

- Flow measurement

- Level/depth measurement

- leak detection

Related application explanation

Motor pressure switch|Water pressure switch|Principle of pressure switch|Air pressure switch|Pressure switch English|Pressure switch setting|Gas pressure switch|Fire pressure switch|pbg ps|ps pbg|ps phg

Related encyclopedias

Pressure sensors can be classified by the pressure range they can measure, the operating temperature, and the type of pressure; the most important of which is the type of pressure. According to the classification method of pressure type, pressure sensors can be divided into the following five categories:

Absolute pressure sensor:

This pressure sensor measures the true pressure of the fluid, that is, the pressure relative to the vacuum pressure. The absolute atmospheric pressure at sea level is 101.325kPa (14.7 PSI).

Gauge pressure sensor:

This kind of pressure sensor can measure the pressure relative to the atmospheric pressure at a specific location. The tire pressure gauge is an example. When the tire pressure gauge shows a reading of 0PSI, it means that the pressure inside the tire is equal to the atmospheric pressure, which is 14.7PSI.

Vacuum pressure sensor:

This kind of pressure sensor is used to measure the pressure less than one atmosphere. Some vacuum pressure sensors in the industry read relative to one atmosphere (the reading is negative), and some are based on the absolute pressure.

Differential Pressure Gauge:

This instrument is used to measure the pressure difference between two pressures, such as measuring the pressure difference between the two ends of the oil filter. The differential pressure gauge is also used to measure the flow rate or measure the liquid level in the pressure vessel.

Seal pressure sensor:

This instrument is similar to a gauge pressure sensor, but it is specially calibrated to measure pressure relative to sea level.

Pressure sensors are sensors used to measure the pressure of liquids and gases. Similar to other sensors, the pressure sensor converts pressure into an electrical signal output when it works.

Pressure sensors are used extensively in many monitoring and control applications. In addition to direct pressure measurement, pressure sensors can also be used to indirectly measure other quantities, such as liquid/gas flow, velocity, water surface or altitude.

Pressure sensors vary greatly in technology, design, performance, working conditions and prices. It is roughly estimated that there are more than 60 types of pressure sensors in the world and at least 300 companies produce pressure sensors.

At the same time, there is also a class of pressure sensors designed to dynamically measure high-speed changing pressures. Example applications are the monitoring of combustion pressure in engine cylinders or the pressure of gases in turbine engines. Such sensors are typically fabricated from piezoelectric materials, such as quartz.

Some pressure sensors, such as those used in traffic enforcement cameras, operate in binary mode, that is, when the pressure reaches a certain value, the sensor controls the circuit to be turned on or off. This type of pressure sensor Also known as a pressure switch.

Power Requirements

Constant current source and constant pressure source are two kinds of excitation commonly used in pressure sensor. The two incentive methods are different and have different effects. Constant current source excitation is beneficial to the compensation of thermal sensitivity drift. Because the temperature coefficient of the bridge arm resistor is positive, and the sensitivity temperature coefficient is negative. The temperature coefficient of the output signal voltage under constant current excitation is the algebraic sum of the two. The constant voltage excitation cannot directly provide the effect of sensitivity temperature compensation. However, a thermistor or diode can be connected in series outside the bridge to compensate for thermal sensitivity drift when using a constant voltage source. With cross-current excitation, this sensitivity compensation method does not work. It can be seen that the excitation of the constant voltage source and the constant current source cannot be interchanged at will.

The purpose of the pressure transmitter is to measure the pressure locally and output the pressure signal to the display (usually installed in the central control room and the instrument panel). What principle does the pressure transmitter use to accomplish this? To understand the working principle of the pressure transmitter, you must first understand two proper terms: 1. Strain gauge: When a conductor is stretched by an external force, it will not be broken or permanently deformed, but will become narrower and longer , this deformation causes its terminal resistance to increase.

| Control | DDC, IoT, MCU, PLC |

|---|---|

| Application | Pressure Sensor |

| Types of | Electronic |

| Installation method | mouth, plate |

| Output method | switch, analogy |

| Application | Factory |

| Types of | Control panel |

Technical Specifications

| SPECIFICATIONS | FGT20C-¨-¨

(Compound) |

FGT20V-¨-¨

(Vacuum) |

FEG20P-¨-¨

(Positive) |

||||

| Rated pressure range | -100.0 ~ 100.0kPa | 0.0 ~ -101.3kPa | 0.000 ~ 1.000MPa | ||||

| Operating /Setting pressure range | -100.0 ~ 100.0kPa | 10.0 ~ -101.3kPa | -0.100 ~ 1.000MPa | ||||

| Withstand pressure | 3 times of rated pressure range | 1.5 times of rated pressure range | |||||

| Fluid | Air, Non-corrosive gases ,incombustible gases | ||||||

| Set Pressure

resolution resolution |

kPa | 0.1 | ─ | ||||

| MPa | ─ | 0.001 | |||||

| Kgf/cm2 | 0.001 | 0.01 | |||||

| bar | 0.001 | 0.01 | |||||

| psi | 0.01 | 0.1 | |||||

| lnHg | 0.1 | ─ | |||||

| mmHg | 1 | ─ | |||||

| mmH2O | 0.1 | ─ | |||||

| Power supply voltage | 12 to 24VDC ±10%, Ripple (PP)10% or less | ||||||

| Current consumption | ≦55mA | ||||||

| Switch out | NPN or PNP open collector 2 outputs

Max. load current: 80mA Max. supply voltage: 30VDC Residual voltage :≦1V (load current 80mA) |

||||||

| Repeatability(Switch output) | ≦±0.2%FS ±1digit | ||||||

| Hysteresis | Hysteresis mode | Adjustable | |||||

| Window comparator mode | Fixed(3 digits) | ||||||

| response time | ≦2.5ms (chattering-proof function: 24ms, 192ms and 768ms selections) | ||||||

| Output short circuit protection | Yes | ||||||

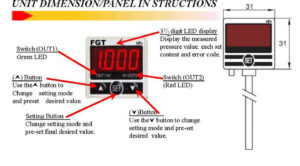

| 7 segment LED display | 3 1/2 digit LED display (Sampling rate:5times/1sec.) | ||||||

| Indicator accuracy | ≦±2% FS ±1 digit (ambient temperature:25 ±3˙C) | ||||||

| Indicator | Green LED (OUT1) Red LED (OUT2) | ||||||

| Analog output

*(only type FGT20¨-01-¨ ,FGT20¨-03-¨) |

Output voltage: 1 to 5V≦±5% FS

(within rated pressure range) Linearity:≦±1% FS |

Output voltage: 1 to 5V ≦±2.5%F.S.

(within rated pressure range) Linearity: ≦±1% FS |

|||||

| Environment | Enclosure | IP40 | |||||

| Ambient temp. range | Operation: 0 ~ 50˙C, Storage:-20 ~ 60˙C (No condensation or freezing) | ||||||

| Ambient humidity range | Operation/Storage: 35 ~ 85% RH (No condensation) | ||||||

| Withstand voltage | 1000VAC in 1-min (between case and lead wire) | ||||||

| Insulation resistance | 50Mohm min. (at 500VDC M, between case and lead wire) | ||||||

| Vibration | Total amplitude 1.5mm, 10Hz-55Hz-10Hz scan for 1 minute, two hours each direction of X, Y and Z | ||||||

| Shock | 980m/s2(100G),3 times each in direction of X,Y and Z | ||||||

| Temperature characteristic | ≦±2% FS of detected pressure (25˙C) at temp. Range of 0~50˙C | ||||||

| Port size | F1:1/8”PT, F2:1/8”NPT, F3:G1/8” | ||||||

| Lead wire | Oil-resistance cable (0.15mm2) | ||||||

| Weight | Appro*105g(with 2-meter lead wire),Appro*71g(with male connector) | ||||||

Accessories