FGT think your best choice in the future

System Integration Designers in FGT

Digital Panel Meter Model MT4Y/MT4W Series with Multiple Input/Output Options

MT4Y/MT4W series centralized digital panel meter

With a variety of input and output options, it can be used flexibly in different environments.

The unit can display the measured value between -1999 and 9999, and has a variety of user-friendly functions, including high/low limit display scale, AC frequency measurement, zero adjustment, and photovoltaic transmission output scale functions.

MT4Y series meter's

Dimensions are DIN W 96 x H 48 mm,

MT4W series meter's

Dimensions are DIN W 72 x H 36 mm.

MT4Y/MT4W Series Centralizeddigital panel meter

With a variety of input and output options, it can be used flexibly in different environments.

The unit can display the measured value between -1999 and 9999, and has a variety of user-friendly functions, including high/low limit display scale, AC frequency measurement, zero adjustment, and photovoltaic transmission output scale functions.

MT4Y series meter's

Dimensions are DIN W 96 x H 48 mm,

MT4W series meter's

Dimensions are DIN W 72 x H 36 mm.

main feature

- Various input/output options (by model)

- – Input options: DC voltage, DC current, AC voltage, AC current

- – Output options: RS485 communication output, low-speed serial output, BCD dynamic output, transmission output (DC 4-20mA), NPN/PNP open collector output, relay contact output (default option: indicator light/no output)

- Maximum allowable input: 500VDC, DC 5A, 500VAC, AC 5A

- Display range: -1999 to 9999

- Upper and lower limit display scale function

- AC frequency measurement (range: 0.1 to 9999Hz)

- Multiple functions: peak display value monitoring, display cycle delay, zero adjustment, peak display value correction, PV transmission output (DC 4-20mA) scale, etc.

- Power supply: 12-24VDC, 100-240VAC

Application

-

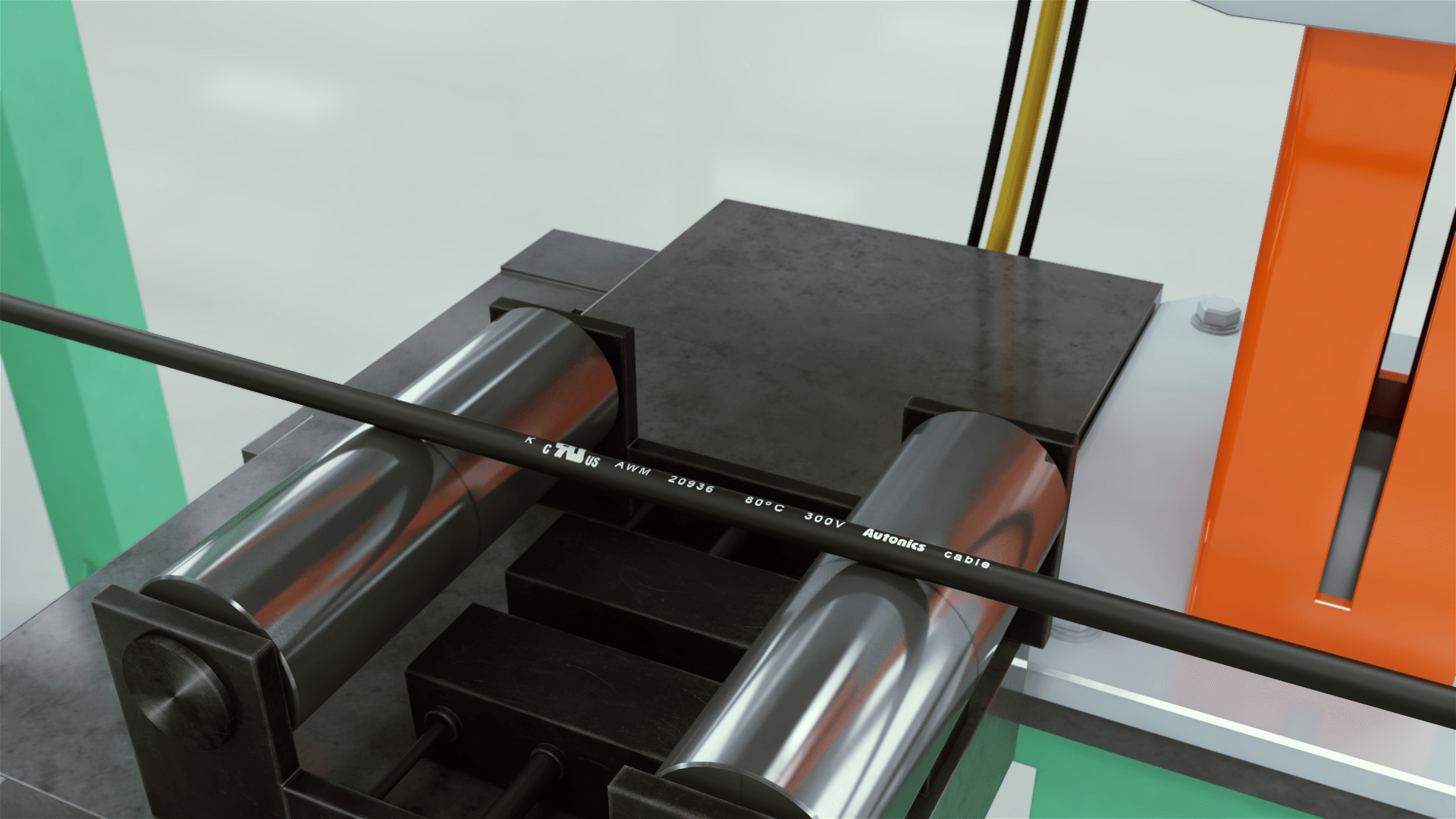

Rubber Extrusion/Plastic Injection Molding Equipment

Digital Panel Meterinformation

Digital Panel Meteris a digital display designed to be installed in a panel such as a control panel. They usually read some type of input, be it voltage, current, or resistance, and display its value digitally. Typically, this input is a measurement from a sensor that is converted and displayed as temperature, pressure, or other system variable. These meters can also act as simple controllers, triggering a switch or performing a simple function when a reading reaches a preset measurement.

Function

To choose a digital panel meter, industrial buyers must first decide what they want to do.

Basic display output

allDigital Panel MeterThe basic function performed is to take the input signal and convert it to a display value. This input initially comes from a sensor in the process or system and is sent to the device through the panel to which the meter is connected. This panel provides power to the device and provides input to the display.

basicDigital Panel Metersignal flow

Additional output

In addition to simple displays, someDigital Panel MeterThere are also optional control or interface functions.

- simulationFunctional means that a device can provide an analog output (such as a variable voltage or current) proportional to the input signal, for use in an analog device.

- Data interfaceFeatures allow users to interact with information displayed for data analysis.

- set pointFunctions allow the user to preset input values that will activate an alarm or simple control function. These on/off functions correspond to solid state or electromechanical relay outputs, depending on the design.

Flowchart – Dual Channel Function with Additional Optional Outputs. Image Credit: Laurel Electronics

Types of

Once buyers have determined which features they need, the actual type of meter also needs to be considered.

Digital Panel MeterDifferentiated by type based on their display and lighting technology.

show performance

Digital Panel Meteris displayed numerically or alphanumerically.

- numberDisplay means that the meter only displays numbers. Most digital panel meters are digital because the main purpose of the meter is to display numerical values.

- letter and numberDisplay means that the meter displays both numbers and letters. This is useful for providing more information to the user, such as the corresponding channel or unit to read.

Technology

The lighting used in digital displays is LED or LCD.

- led(Light Emitting Diode) The display consists of diodes that light up the segments. The LED display can be seen in the dark.

LCD(Liquid Crystal Display) technology to display dark/black numbers on a blank grey or green screen. LCDs consume less power than LEDs, but require a backlight to see in the dark.

LCD(Liquid Crystal Display) technology to display dark/black numbers on a blank grey or green screen. LCDs consume less power than LEDs, but require a backlight to see in the dark.

Signal input type

In order to work properly, the device must be designed to accept the analog input sent to it. Input types include:

- AC voltage– Input is received as a measurable form of AC voltage in AC voltage (VAC).

- Alternating current– Enter the AC current sink in a measurable form in milliamps (mA AC) or amps (A AC).

- AC power– Inputs are received as adjustable ranges for AC current, voltage and/or frequency.

- DC voltage– Inputs are received as a measurable DC voltage in Volts Direct Current (VDC).

- DC– Enter a measurable form of DC current sink in milliamps (mA DC) or amps (A DC).

- DC power supply– Inputs are received as adjustable ranges for DC current, voltage and/or frequency.

- resistance– Inputs come from components that measure resistance changes, e.g.Piezoresistive sensororstrain gauge.

- Temperature Controller-According to temperature changes fromThermocouple,RTDorThermistorReceive input. For more information, seeTemperature Sensorarea.

Specification

There are some important specifications to consider when choosing a digital panel meter, all of which relate to the display itself. These include the number of bits, the size of the panel face, and the display color.

number of digits

The number of digits determines how many digits are in the display output. This number should be less than or equal to the number of significant digits in the signal input, depending on the desired precision. Displays half digits at nominal (e.g. 4 .5digits, 2 .5digit), the first or last digit can only be "1" or off, or "5" or off. This "half" number allows the upper limit of the display to be extended (1 000 vs. _999) or allow to display intermediate values (100. 5 vs. 100_).

size

The size of the panel face determines the physical compatibility of the device with the panel on which it is installed. Typically, face dimensions are in inches (” or in) or millimeters (mm) and are specified by length and width. Sometimes, the depth of the gauge and the size of the cutout need to be considered, although most panels will accept standard depth and face dimensions Related. Also, the display should be large enough for the user to read the numbers/letters comfortably when installed.

colour

Digital panel meters are designed to display certain colors. In LCD meters, the color is determined by the backlight behind the black numerals. In LED meters, the color is determined by the type of diode built into the device. Color options include:

- Red

- green

- amber

- blue

- yellow

- tangerinr

- aquarium

Red is the default LED color, usually LCDs have no backlight (no color). Multicolor options exist, which are especially useful when using multiple monitors or channels. Setting a color for each monitor can help users quickly identify each monitor.

connect

digital display instrumentThe connections include electrical inputs and outputs as well as physical connections (such as screw connectors) necessary for safe mounting to the panel. These connections must be compatible with the design and regulations of the relevant panel.

feature

Digital Panel MeterMay contain many functions that provide additional functionality to the device. These include set point options, alarms, on/off controls and adjustable displays.

- Set point optionsAbility to set control limits or set points for process parameters such as speed, temperature, pressure or humidity. In heating applications, the unit sends an off control signal when the set point temperature is approaching or exceeded, and an on control signal when the temperature is below the set point.

- Can be built into the meteralarm(audio or visual) to indicate when a limit or set point is reached.

- On/Off ControlAllows the meter to send a switch output signal to activate or deactivate a processing unit (oven, motor, fan, etc.) using relays, open collector transistors, or other techniques. Switch, pop or limit control is one of the simplest process control techniques.

- adjustable displayAllows the gauge to be adjusted to show different displays.

- Additional channelAllows digital panel meters to receive and interpret multiple signals from different sources.

- USB/Serial PortAllows the meter to connect to other devices, such as data analysis tools or computers, via a USB or serial connector.

The principle of timer counter table | Our performance

Rotary encoderprinciple| Our performance

Photoelectric switch principle | Our performance

Principle of safety grating | Our performance

Proximity switch principle | Our performance

Principle of digital display meter | Our performance

Stepper Motor &Drive principle | Our performance