FGT think your best choice in the future

System Integration Designers in FGT

Machine Vision System | nVision-i Series | Image Control Software | DISORIC

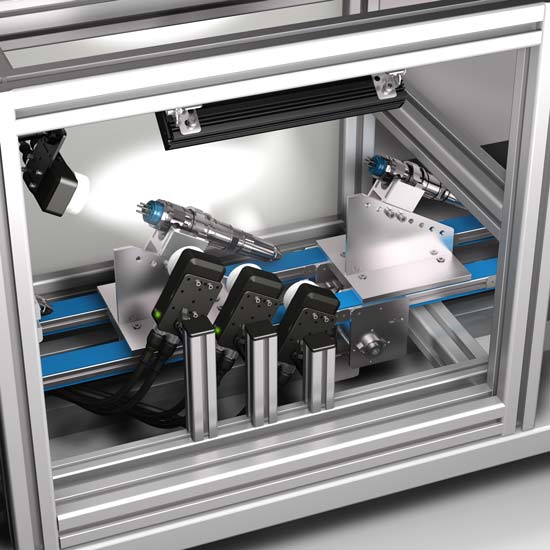

German manufacturer DISORIC (First General Machinery Co., Ltd.) | 18 years as the sole distributor | PLC engineering technology with practical engineering experience | Machine vision systems | nVision-i series | Image control software

Software can be switched (German, English, French, Italian, Spanish, Chinese, and KoreanIt can be further developed and connected to an AI engine, saving manual labor.

- Description

- Additional information

- Product Specifications

- Product accessories and software

- Special needs

- Inquire now

Machine Vision System | nVision-i Series | Image Control Software | DISORIC

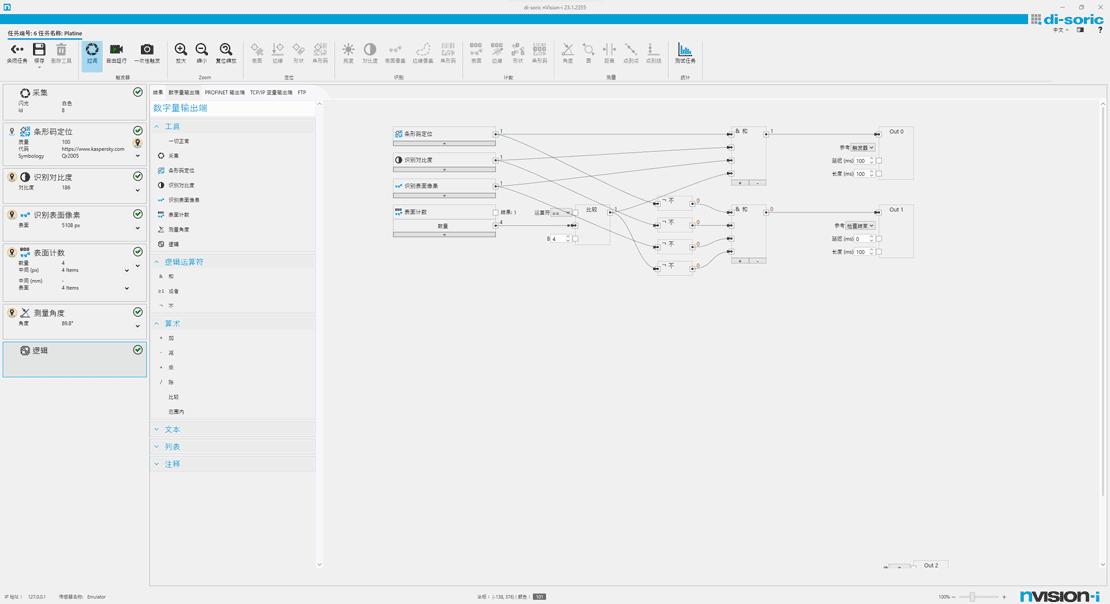

- nVision-i is used to program and configure parameters for your PC's CS-60 vision sensor and ID-600 fixed barcode reader. It includes a simulator that can be used to emulate both devices.

Leveraging the expertise of FGT's engineering team in AI (Artificial Intelligence) and BI (Big Data), we can quickly assist you in building an AI+AOI system solution.

No need to hire professional human resources personnel; the driving force behind commissioned projects to create mobile-enabled machine vision platforms.

Advantages and characteristics

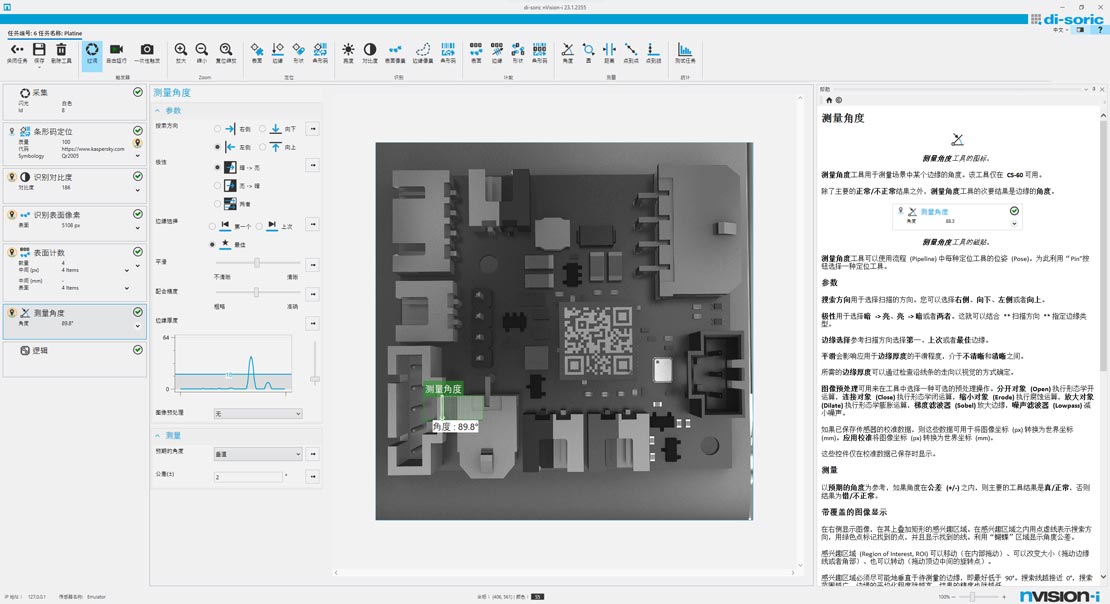

interface

Process and Status Detection

You can insert inspection tools here and move them by dragging and dropping.

This section displays the measured values and inspection results/inspection status.

Guide Columns and Inspection Tools

Intuitive user-friendly navigation menu

Context-sensitive assistance can be displayed when necessary.

The menu navigation is available in 7 languages.German, English, French, Italian, Spanish, Chinese, and Korean)

Configuration

- The parameters for the search criteria can be set directly and easily.

- The limit values of the analysis standard can be easily entered.

Display and drawing tools

- Viewing images during operation for control and analysis.

- The right side contains a contextual description of the tool, allowing users to fully utilize all its features.

Image processing tools

Simple and fast

A wide variety of image processing tools can verify the quality and integrity of parts, locate parts, and transmit the determined position through various communication interfaces.

It can reliably perform even demanding tasks, such as quality inspection of highly reflective objects, applications with constantly changing ambient light, or high-speed applications.

For CS-60

Does the identification feature based on pixel value and contrast exist?

brightness

The average brightness is determined based on the threshold range within a defined area in the image.

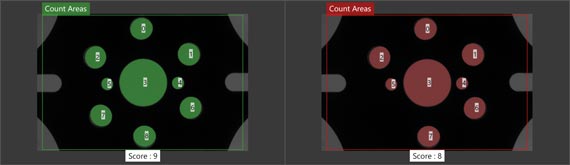

Surface pixels

The number of pixels is determined based on the threshold range within a defined region in the image.

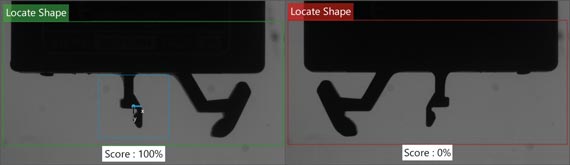

Positioning surfaces, edges, and shapes

surface

The "Surface Localization" tool is used to locate a specific part of a scene using Blob analysis.

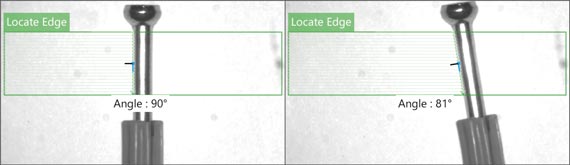

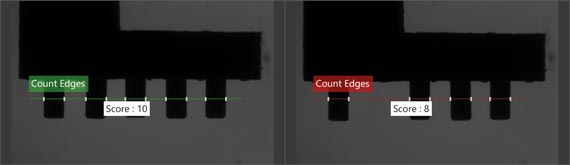

edge

Find an edge in the defined search field, which can then be used for tracking in subsequent tools.

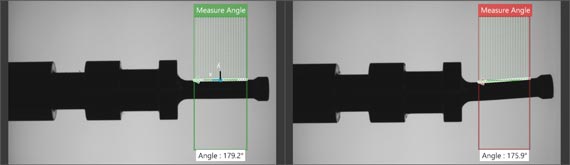

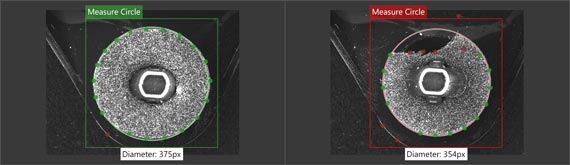

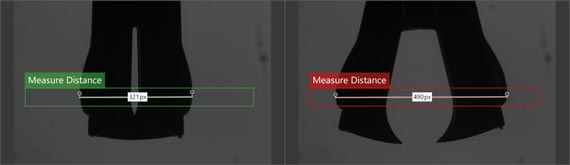

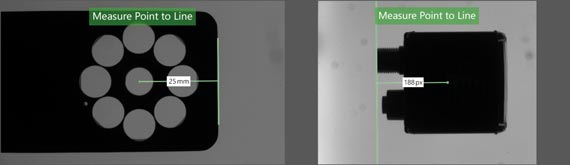

Calculate surfaces, edges, and shapes

Measure angles, diameters, distances, and ranges in millimeters and pixels.(Available after upgrade)

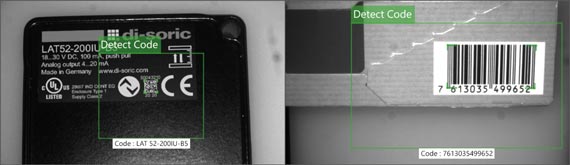

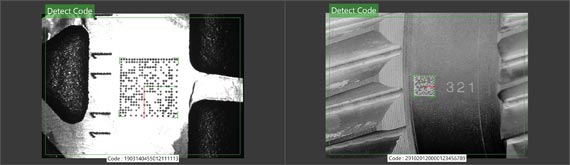

Locating and reading 1D and 2D barcodes(Available after upgrade)

position

Find a code in the defined search field, which can then be used for tracking in subsequent tools. Efficiently check tag locations.

For ID-600

Locating and reading 1D and 2D barcodes

position

Find a code in the defined search field, which can then be used for tracking in subsequent tools. Efficiently check tag locations.

Reading Direct Markup Codes (DPM) on surfaces that are not easily identifiable. (Available after upgrade)

Logic tools

Associate the results with the output.

By freely associating the results of multiple tool drag-and-drop guidance methods, a total result can be obtained directly in the vision sensor, thereby achieving excellent working performance without increasing the load on the PLC.

Another advantage is its high flexibility:

Measurements or results can be addressed at any point on the Profinet fieldbus.

Quick to learn and use, no training required: Graphical logic tools

Based on Functional Graphs (FDPs), even extremely complex functions can be clearly displayed. This allows for simple and easy-to-understand implementation of input and output behaviors.

This eliminates the need for training, as the operating procedures are already familiar from the daily processing of PLC programming.

Image correction and calibration

Integrated Image Optimization

Calibration via nVision-i can be performed with just two clicks, easily eliminating distortion and shadows at the edges of images. Therefore, the vision sensor is capable of converting pixel values to precise actual values (in millimeters) across the entire field of view and outputting them.

In addition, the CS-60 can meet the requirements of fields where flexibility, ease of configuration, and rapid conversion are crucial.

Visualize the inspection results in a web browser.

The display of test results in a web browser is easy to understand, even for untrained employees, and has become an indispensable tool in the monitoring process. Our vision sensors' web interface is compelling because it provides a complete overview through tools that directly display measurements and borders within the image.

Process and Status Detection

- Display inspection tools

- This section displays the measured values and inspection results/inspection status.

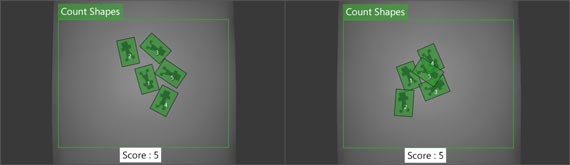

The results show

- green box and: normal

- Red box and: Abnormal

Visualization

- Use checkboxes to visually filter the visualization tools and their results in the image window:

Simply turn the area and results you want to display on or off. - The examination results are displayed directly in the imaging window.

Historical records

- Displays inspection history and status.

- You can review past recordings again.

Easily access via IP address

Open a web browser, enter the IP address, and return—the image processing toolset and its results are displayed without any further steps. Live view allows you to directly view the currently captured images in the vision sensor's field of view, as well as the history of image acquisition—filtered by successful and unsuccessful checks.

What is machine vision?

What are the principles of visual recognition?

Machine vision (MV) refers to an imaging-based method for automated inspection and analysis, widely used in industrial automation inspection, process control, and robot guidance. It encompasses various technologies, software and hardware products, integrated systems, motion, methods, and expertise. As a system engineering discipline, machine vision is considered distinct from computer vision, which belongs to computer science. It attempts to integrate existing technologies in new ways and apply them to practical problem-solving. The entire machine vision process includes planning requirements and project details, followed by solution development. During system execution, imaging begins, followed by automated image analysis and extraction of necessary information.

Main application areas

Machine vision technology is widely used in industrial production and automation scenarios:

- Automated Optical Inspection (AOI): Detects defects, flaws, or incorrect assembly on the surface of a product.

- Quality control: Ensure that the product size, shape, or color meets the standards.

- Positioning and guidance: Guiding the robot to accurately grasp, place, or assemble parts.

- Identification: Reading barcodes, QR codes, text, or identifying objects.

- Measurement: To perform precise, non-contact dimensional measurements of an object.

Difference from Computer Vision

Although the two are closely related and their technologies overlap, their focuses are different:

Machine vision: focuses more on practical applications in industrial automation, emphasizing system integration, stability and efficiency to solve specific engineering problems.

Computer vision: focuses more on theoretical research and algorithm development. It is a branch of artificial intelligence and aims to enable computers to "understand" image content and simulate the complex visual cognitive abilities of humans.

Automated Optical Inspection (AOI) is a high-speed, high-precision optical imaging inspection system that uses machine vision as the standard inspection technology. It improves upon the shortcomings of traditional manual inspection using optical instruments. Its applications range from R&D and manufacturing quality control in high-tech industries to defense, consumer goods, medical care, environmental protection, power, and other fields.

Automated optical inspection is a common and representative method in industrial processes. It uses optical instruments to obtain the surface condition of finished products, and then uses computer image processing technology to detect defects such as foreign objects or pattern anomalies. Because it is a non-contact inspection, it can be used to inspect semi-finished products in intermediate processes. High-precision optical image inspection systems encompass fields such as measurement lens technology, optical illumination technology, positioning measurement technology, electronic circuit testing technology, image processing technology, and automation technology applications. Its development and application not only meet the needs of high-tech industry development, but its technology can also be extended to the defense and military industry. For example, the manufacturing of military weapons, night vision combat systems, and the analysis and assessment of strategic terrain features are all closely related to this imaging technology.

machine vision market competitive

American Machine Vision Market

European machine vision market

machine vision market south

| Types of | Electronic |

|---|---|

| Installation method | Thread |