FGT think your best choice in the future

System Integration Designers in FGT

Machine Vision System | BE-F Series | Backlight | DISORIC

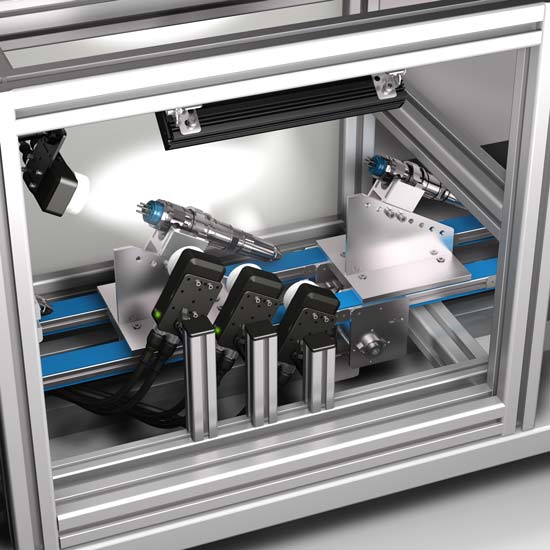

German manufacturer DISORIC (First General Machinery Co., Ltd.) | 18 years as the sole distributor | PLC engineering technology with practical engineering experience | Machine vision systems | nVision-i series | Image control software

Software can be switched (German, English, French, Italian, Spanish, Chinese, and KoreanIt can be further developed and connected to an AI engine, saving manual labor.

- Description

- Additional information

- Product Specifications

- Product accessories and software

- Special needs

- Inquire now

Machine Vision System | BE-F Series | Backlight | DISORIC

- Area lighting is used to illuminate the background and inspect contours, and can therefore be used in a camera overhead view for contour detection of numerous objects whose contours must be monitored. The lighting system offers a choice of color temperatures relevant to all applications and can be used for objects ranging in size from 30 x 30 mm to 200 x 200 mm.

- Featuring a high-density LED array design, it provides high-intensity backlighting and highlights the shape and contour features of objects, making it particularly suitable as a stage for microscopes.Backlights come in various types, such as red-white dual-use backlights and red-blue dual-use backlights. By mixing different colors, the multi-color requirements of different tested objects can be met.

It can be applied to scenarios such as measuring the size of mechanical parts, detecting electronic components, detecting the shape of chips, detecting stains on film, and detecting scratches on transparent objects.

Leveraging the expertise of FGT's engineering team in AI (Artificial Intelligence) and BI (Big Data), we can quickly assist you in building an AI+AOI system solution.

No need to hire professional human resources personnel; the driving force behind commissioned projects to create mobile-enabled machine vision platforms.

Advantages and characteristics

- High lighting intensity

- Minimum edge range

- Uniform lighting area

- Very compact form

- High protection rating IP 67

- robust structure

External backlight can flash

- High overcurrent coefficient

- Pulse operation used to inspect fast-moving targets

- Extremely bright, used for high depth of field

- Achieving a long service life through intelligent thermal management

- Uniform lighting area

- High protection rating IP 67

- Sturdy metal casing

Characteristics of machine vision backlights:

1. It has better uniformity

2. The light is soft and natural, with high brightness.

3. Customizable multi-color backlighting, suitable for special occasions.

4. High-density LEDs are distributed at the bottom of the light source.

Machine vision light source usagePrecautions

Using LEDs in high-temperature environments shortens their lifespan.

*Especially for red LEDs, the brightness will decrease by 1% for every 1 degree Celsius increase in temperature.

* Prolonged use at high temperatures will gradually cause aging and reduce brightness.

How to use light sources correctly to prevent aging and brightness reduction caused by self-heating.

■ Use the light source at the lowest possible brightness level.

At suitable brightness levels, the light source level is reduced to decrease current consumption, thus generating less heat and preventing brightness loss. If brightness decreases due to prolonged use, the brightness level can be gradually increased.

■ A fan can be installed or airflow can be provided to dissipate heat, reduce temperature, and slow down the decline in brightness.

Install a fan to provide airflow—install a bracket with good heat dissipation.

■ The light source can be turned on only during imaging or a strobe controller can be used.

Repeated switching of an LED light source on and off has virtually no impact on its lifespan. When the LED is used as a strobe light source or is turned on only according to external signal requirements, the light source brightness is stable and the LED lifespan will be significantly extended.

Machine vision light source selectionPrecautions

1. Understand the system structure and operational requirements, and determine the spatial relationship between the camera, light source, and object being measured. The parameters to be determined include: field of view (FOV) and working distance (WD).

2. Spatial structures include: direct sunlight, side sunlight, and back sunlight.

- Direct-type light sources include some ring light sources, coaxial light sources, and dome light sources.

- Side-emitting light sources include some types such as ring light sources, strip light sources, line light sources, and point light sources.

- Backlighting can be achieved using a square backlight, a strip backlight, or a U-shaped backlight.

3. Observation and analysis of the object being tested: Dome light source is suitable for curved surfaces, coaxial light source is suitable for smooth planes, bright-field light source is suitable for rough planes, and infrared light source can be used for objects with good light transmission. Distinguish the color of the back (which we do not need to test) and the color of the foreground (which we need to test).

4. Good light sources can improve image contrast – if the background and foreground are clear and the foreground has many color variations, colored or white light sources are recommended.

Types and characteristics of LED light sources

1. Ring light source

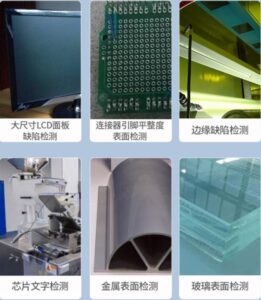

Offering different illumination angles and color combinations to better highlight the three-dimensional information of objects; high-density LED array for high brightness; various compact designs to save installation space; solves the problem of shadows from diagonal illumination; optional diffuser plate for uniform light diffusion. Applications include PCB substrate inspection, IC component inspection, microscope illumination, LCD calibration, plastic container inspection, and integrated circuit marking inspection.

2. Backlight

High-intensity backlighting with a high-density LED array effectively highlights the shape and contours of objects, making it particularly suitable as a microscope stage. Dual-use (red/white) and multi-use (red/blue) backlights can be configured to produce different colors to meet the multi-color requirements of various measured objects. Applications include dimensional measurement of mechanical parts, shape inspection of electronic components and ICs, detection of film stains, and scratch detection on transparent objects.

3. Bar light source

It is the preferred light source for test objects with large square structures; the color can be customized and freely combined according to requirements; the illumination angle and installation are adjustable. Applications include metal surface inspection, image scanning, surface crack detection, and LCD panel inspection.

4. Coaxial light source

It can eliminate shadows caused by uneven object surfaces, thereby reducing interference; part of it adopts a beam splitter design to reduce light loss, improve image clarity, and uniformly illuminate the object surface. It is best suited for scratch detection on highly reflective objects, such as metal, glass, film, and wafer surfaces; damage detection of wafers and silicon wafers; mark point positioning; and packaging barcode recognition.

5. AOI dedicated light source

It features tri-color light illumination from different angles, which can highlight the three-dimensional information of the solder; an additional diffuser board guides the light and reduces reflection; different angle combinations; applicable to circuit board solder inspection.

6. Spherical Integral Light Source

The hemispherical inner wall, with its integrating effect, uniformly reflects light emitted from the bottom 360 degrees, resulting in highly uniform illumination across the entire image. It is applicable to the inspection of curved surfaces, uneven surfaces, arc-shaped surfaces, or highly reflective surfaces such as metals and glass.

7. Linear light source

Ultra-high brightness, using cylindrical lenses for light focusing, suitable for various continuous detection applications on production lines. Dedicated for array camera illumination and AOI (Automated Optical Inspection) applications.

8. Point light source

High-power LEDs, small in size and high in luminous intensity; a replacement for fiber optic halogen lamps, particularly suitable as coaxial light sources for lenses; high-efficiency heat dissipation device significantly extends the lifespan of the light source. Suitable for telecentric lenses, used for wafer inspection, mark point positioning, and wafer and LCD glass substrate calibration.

9. Combined bar light source

With four-sided strip lighting, each side's illumination is independently controllable; the required illumination angle can be adjusted according to the object being tested, making it widely applicable. Applications include PCB substrate inspection, IC component inspection, solder joint inspection, mark point positioning, microscope illumination, packaging barcode illumination, and spherical object illumination.

10. Alignment light source

It is a dedicated light source for alignment on fully automatic circuit board printing machines. The alignment light source is fast, has a wide field of view, high precision, small size, is convenient for detection and integration, has high brightness, and can be equipped with an auxiliary ring light source.

What is machine vision?

What are the principles of visual recognition?

Machine vision (MV) refers to an imaging-based method for automated inspection and analysis, widely used in industrial automation inspection, process control, and robot guidance. It encompasses various technologies, software and hardware products, integrated systems, motion, methods, and expertise. As a system engineering discipline, machine vision is considered distinct from computer vision, which belongs to computer science. It attempts to integrate existing technologies in new ways and apply them to practical problem-solving. The entire machine vision process includes planning requirements and project details, followed by solution development. During system execution, imaging begins, followed by automated image analysis and extraction of necessary information.

Main application areas

Machine vision technology is widely used in industrial production and automation scenarios:

- Automated Optical Inspection (AOI): Detects defects, flaws, or incorrect assembly on the surface of a product.

- Quality control: Ensure that the product size, shape, or color meets the standards.

- Positioning and guidance: Guiding the robot to accurately grasp, place, or assemble parts.

- Identification: Reading barcodes, QR codes, text, or identifying objects.

- Measurement: To perform precise, non-contact dimensional measurements of an object.

Difference from Computer Vision

Although the two are closely related and their technologies overlap, their focuses are different:

Machine vision: focuses more on practical applications in industrial automation, emphasizing system integration, stability and efficiency to solve specific engineering problems.

Computer vision: focuses more on theoretical research and algorithm development. It is a branch of artificial intelligence and aims to enable computers to "understand" image content and simulate the complex visual cognitive abilities of humans.

Automated Optical Inspection (AOI) is a high-speed, high-precision optical imaging inspection system that uses machine vision as the standard inspection technology. It improves upon the shortcomings of traditional manual inspection using optical instruments. Its applications range from R&D and manufacturing quality control in high-tech industries to defense, consumer goods, medical care, environmental protection, power, and other fields.

Automated optical inspection is a common and representative method in industrial processes. It uses optical instruments to obtain the surface condition of finished products, and then uses computer image processing technology to detect defects such as foreign objects or pattern anomalies. Because it is a non-contact inspection, it can be used to inspect semi-finished products in intermediate processes. High-precision optical image inspection systems encompass fields such as measurement lens technology, optical illumination technology, positioning measurement technology, electronic circuit testing technology, image processing technology, and automation technology applications. Its development and application not only meet the needs of high-tech industry development, but its technology can also be extended to the defense and military industry. For example, the manufacturing of military weapons, night vision combat systems, and the analysis and assessment of strategic terrain features are all closely related to this imaging technology.

machine vision market competitive

American Machine Vision Market

European machine vision market

machine vision market south

| Types of | Electronic |

|---|---|

| Installation method | Thread |