FGT think your best choice in the future

System Integration Designers in FGT

- 簡化的設置和診斷功能。

- 具備溫度和壓力補償

- 4〜20mA/脈衝輸出/MODBUS RTU輸出。

- 多種尺寸可供選擇。

- 溫度範圍高達420oC

- 具備記憶功能暫存器,用於設置和校準。

- 支持:NB-IOT開發

- Wifi功能支持SMM雲端感測器軟體

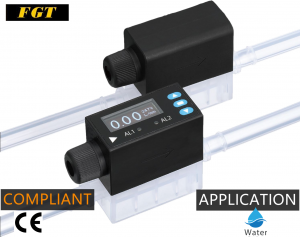

- 符合設計標準:EX-ATEX/CE/IP67/UL/IEC/SGS

什麼是渦流流量計

渦流流量計的組成

渦流流量計,包括:流量感測器,其可操作以感測由於流體在通道中的渦流脫落引起的壓力變化,並將壓力變化轉換為電信號形式的流量感測器信號;以及信號處理器,其用於接收流量感測器信號,並生成與由於通道中流體渦流脫落而引起的壓力變化相對應的輸出信號。

工作原理

當介質以一定速度流過布拉夫體時,在布拉夫體側面的後面會產生交替排列的渦流帶,稱為“馮·卡爾曼渦流”。由於渦流發生器的兩側交替產生渦流,因此在發生器的兩側都會產生壓力脈動,這會使檢測器產生交變應力。封裝在檢測探頭主體中的壓電元件在交變應力的作用下產生與渦旋頻率相同的交變電荷信號。這些脈衝的頻率與流量成正比。信號經過前置放大器放大後,發送到智能流量累加器進行處理

在雷諾數的一定範圍內(2×10 ^ 4〜7×10 ^ 6),渦流釋放頻率,流體速度和渦流產生器面對流動表面寬度之間的關係可以用以下公式表示:

f=St×V/d

其中,f是卡門渦流的釋放頻率,St是Strouhal數,V是速度,d是三角形圓柱的寬度。

渦流流量計的應用

1.智慧管道監控應用

流量計在工業應用中很受歡迎的主要原因是其設計和製造方式。它們沒有運動部件,幾乎沒有阻礙直通的流路,不需要溫度或壓力校正,並在很寬的流量範圍內保持精度。通過使用雙板流量調節元件可以減少直管段,並且安裝非常簡單,並且不會造成管道侵入

但是,在許多應用中,流體的熱性能可能取決於流體成分。在此類應用中,實際操作期間流體成分的變化會影響流測量。因此,對於流量計供應商而言,重要的是要了解流體的成分,以便可以使用適當的校準係數來準確確定流量。供應商可以為其他氣體混合物提供適當的校准信息,但是流量計的精度取決於實際的氣體混合物與用於校準目的的氣體混合物相同。換句話說,如果實際流動的氣體具有不同的成分,則針對給定的氣體混合物校準的流量計的精度將會降低

2.CVD設備

甚麼是CVD設備

氣相沉積(CVD)是一種真空沉積方法,用於生產高質量,高性能的固體材料。該工藝通常在半導體工業中用於生產薄膜

在典型的CVD中,晶片(基材)暴露於一種或多種易揮發的前體中,該前體在基材表面上發生反應和/或分解以產生所需的沉積物。通常還會產生揮發性副產物,這些副產物會被流過反應室的氣流除去

3.氣體分配盤/操作盤 (VMB/VMP)

甚麼是VMB/VMP

通過我們在處理氣體方面的經驗,我們獲得了設計和製造EPI系統,MOCVD,材料供應系統等的面板(氣箱)的知識。

在我們的業務成就中,我們能夠設計和製造滿足客戶要求(價格和規格)的產品。我們不僅可以處理普通氣體,還可以處理輪轂環的液化氣供應。我們還支持各種法律申請.

水流量計\流量計種類\氣體流量計\流量計價格\流量計原理

| 應用 | 流量 |

|---|---|

| 類型 | 電子式 |

| 安裝方式 | 法蘭, 牙口, 夾管, 插入 |

| 輸出方式 | 數位, 類比, 無線 |

技術規格

| 型號 | FVF-F | FVF-W | FVF-I |

| 尺寸(mm/Inch) | DN15(1/2″)~DN600(22″) | DN300(12″)~DN1000(26″) | |

| 接續方式 | 法蘭式 | 對夾式 | 插入式 |

| 流量範圍 | 蒸氣:1.6~540,000 Kg/Hr | ||

| 氣體:3~46,000 M3/Hr | |||

| 液體:0.3~4950 M3/Hr | |||

| 精度 | 氣體&蒸氣:±1.0% of reading | ||

| 液體:±0.7% of reading | |||

| 再現精度 | ±0.2% fo reading | ||

| 溫度範圍 | -40~+280℃(標準型) | ||

| -40~+420℃(選購) | |||

| 環境溫度 | -20~+60℃ | ||

| 耐壓 | 78 kg/cm2(最大.) | ||

| 保護等級 | IP65 | ||

| 防爆等級,Exd IIC T6,Intrinsically Safe,E ex ia IIC T4 | |||

| 顯示器 | 4行LCD,4位即時流量,8位累積流量 | ||

| 電流輸出 | 4~20mA(2-線)/600 Ohm | ||

| 脈衝輸出 | 脈衝(3-線)/Rating:3~30Vdc,20 mA Max | ||

| 通訊方式 | RS-485 | ||

| Wifi_雲端 | Zigbee Wifi 支援SMM雲端感測器軟體 | ||

| 資料儲存 | 操作參數和累積數值暫存EEPROM存儲超過10年以上 | ||

| 接線方式 | 2 X M20*1.5 | ||

| 選購 | 壓力感測器:壓力補償 | ||

| 溫度感測器:溫度補償 | |||

| 供應電壓 | 12~24Vdc | ||

應用領域

什麼是渦街流量計

渦街流量計的組成[編輯]

一種渦流流量計,包括:流量傳感器,可操作以感測由於通道中流體的渦流脫落引起的壓力變化,並將壓力變化轉換為電信號形式的流量傳感器信號;以及信號處理器,可操作以用於 接收流量傳感器信號,並生成與通道中流體渦流脫落引起的壓力變化相對應的輸出信號。 [2]

工作原理[編輯]

當介質以一定速度流過布拉夫體時,在布拉夫體兩側後方產生交替排列的渦帶,稱為“馮卡門渦”。 由於渦流發生器兩側交替產生渦流,在發生器兩側產生壓力脈動,使探測器產生交變應力。 封裝在檢測探頭體內的壓電元件在交變應力作用下產生與渦流頻率相同的交變電荷信號。 這些脈衝的頻率與流速成正比。 信號經前置放大器放大後送至智能流量積算儀進行處理。

在一定的雷諾數範圍內(2×10^4~7×10^6),旋渦釋放頻率、流體速度與旋渦發生器迎流面寬度之間的關係可以用下式表示:[3]

f=St×V/d

其中,f為卡門渦的釋放頻率,St為斯特勞哈爾數,V為速度,d為三角柱體的寬度[4]。

渦街流量計應用

1.智能管道監控器

熱式質量流量計在工業應用中流行的主要原因是它們的設計和製造方式。 它們沒有移動部件,幾乎暢通無阻的直通流路,不需要溫度或壓力校正,並在很寬的流速範圍內保持精度。 使用雙板流量調節元件可以減少直管路,安裝非常簡單,管道侵入最少。

然而,在許多應用中,流體的熱特性可能取決於流體成分。 在此類應用中,實際操作期間流體成分的變化會影響熱流量測量。 因此,對於熱式流量計供應商來說,了解流體的成分非常重要,這樣才能使用適當的校準係數來準確確定流量。 供應商可以為其他氣體混合物提供適當的校准信息,但是熱流量計的精度取決於實際氣體混合物是否與用於校準目的的氣體混合物相同。 換句話說,如果實際流動的氣體具有不同的成分,則針對給定氣體混合物校準的熱流量計的精度將會降低。 [2]

2.CVD機

什麼是化學氣相沉積

化學氣相沉積 (CVD) 是一種真空沉積方法,用於生產高質量、高性能的固體材料。 該工藝通常用於半導體行業生產薄膜。

在典型的 CVD 中,晶圓(基板)暴露於一種或多種揮發性前體,這些前體在基板表面反應和/或分解以產生所需的沉積物。 通常,還會產生揮發性副產物,這些副產物會被流過反應室的氣流去除。

微加工工藝廣泛使用 CVD 沉積各種形式的材料,包括:單晶、多晶、非晶和外延。 這些材料包括:矽(二氧化矽、碳化物、氮化物、氮氧化物)、碳(纖維、納米纖維、納米管、金剛石和石墨烯)、碳氟化合物、燈絲、鎢、氮化鈦和各種高 k 電介質。

3.閥組箱/面板(VMB/VMP)

什麼是VMB/VMP

通過我們處理氣體的經驗,我們獲得了設計和製造EPI系統和MOCVD的氣體面板(氣體箱),材料供應系統等的知識。

在我們的業務成就中,我們能夠設計和製造以滿足客戶的要求(價格和規格)。 我們不僅可以處理普通氣體,還可以處理液化氣體的輪轂環空氣供應。 我們還支持各種法律申請。

流量範圍

| 尺寸 | 飽和蒸氣-Kg/Hr | |||||||||||||||||||

| 絕對壓力 P(Mpa) |

0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | |||||||||||

| (mm) | Inch | 溫度 @4℃ |

120.2 | 133.5 | 143.62 | 151.84 | 158.94 | 164.96 | 170.41 | 175.36 | 179.68 | |||||||||

| 密度 (Kg/m3) |

1.129 | 1.651 | 2.163 | 2.689 | 3.17 | 3.667 | 4.162 | 4.665 | 5.147 | |||||||||||

| 流量範圍 | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | ||

| 20 | 3/4″ | 9 | 80 | 11 | 102 | 12 | 130 | 13 | 160 | 15 | 190 | 16 | 220 | 17 | 250 | 18 | 279 | 19 | 309 | |

| 25 | 1″ | 14 | 136 | 17 | 198 | 19 | 260 | 21 | 320 | 23 | 380 | 25 | 440 | 27 | 499 | 28 | 559 | 30 | 618 | |

| 40 | 1-1/2″ | 32 | 400 | 38 | 498 | 44 | 649 | 48 | 801 | 53 | 951 | 57 | 1100 | 60 | 1249 | 64 | 1397 | 67 | 1544 | |

| 50 | 2″ | 52 | 667 | 64 | 826 | 73 | 1080 | 81 | 1335 | 88 | 1585 | 95 | 1834 | 100 | 2081 | 107 | 2328 | 112 | 2574 | |

| 65 | 2-1/2″ | 88 | 933 | 106 | 1320 | 121 | 1730 | 135 | 2135 | 147 | 2536 | 158 | 2934 | 168 | 3330 | 178 | 3724 | 187 | 4118 | |

| 80 | 3″ | 105 | 1400 | 127 | 1980 | 145 | 2596 | 161 | 3240 | 176 | 4015 | 189 | 4644 | 201 | 5270 | 213 | 5896 | 224 | 6520 | |

| 100 | 4″ | 175 | 2332 | 212 | 3300 | 242 | 4320 | 269 | 5400 | 293 | 6430 | 315 | 7320 | 336 | 8320 | 355 | 9310 | 374 | 10300 | |

| 125 | 5″ | 262 | 3500 | 317 | 4950 | 363 | 6490 | 404 | 8000 | 440 | 9510 | 473 | 11000 | 504 | 12500 | 533 | 14000 | 560 | 15440 | |

| 150 | 6″ | 350 | 4666 | 423 | 6600 | 484 | 8650 | 538 | 10680 | 586 | 1268 | 631 | 14670 | 672 | 16650 | 711 | 18620 | 747 | 20590 | |

| 200 | 8″ | 610 | 9330 | 740 | 13200 | 848 | 17300 | 942 | 21360 | 1026 | 25360 | 1104 | 29340 | 1176 | 33300 | 1243 | 37240 | 1308 | 41180 | |

| 250 | 10″ | 875 | 13997 | 1056 | 19810 | 1210 | 25960 | 1345 | 32030 | 1466 | 38040 | 1577 | 44000 | 1680 | 49940 | 1776 | 55860 | 1868 | 61760 | |

| 300 | 12″ | 1050 | 20995 | 1270 | 29720 | 1453 | 38930 | 1614 | 48040 | 1759 | 57050 | 1892 | 66000 | 2016 | 74900 | 2132 | 83800 | 2241 | 92650 | |

| 尺寸 | 飽和蒸氣-Kg/Hr | |||||||||||||||||||

| 絕對壓力 P(Mpa) |

1.2 | 1.4 | 1.6 | 1.8 | 2.0 | |||||||||||||||

| (mm) | Inch | 溫度 @4℃ |

187.96 | 195.04 | 201.37 | 207.11 | 212.37 | |||||||||||||

| 密度 (Kg/m3) |

6.127 | 7.106 | 8.085 | 9.065 | 10.05 | |||||||||||||||

| 流量範圍 | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | Max. | ||||||||||

| 20 | 3/4″ | 20 | 368 | 22 | 426 | 24 | 485 | 25 | 544 | 26 | 603 | |||||||||

| 25 | 1″ | 33 | 735 | 35 | 853 | 37 | 970 | 39 | 1088 | 42 | 1206 | |||||||||

| 40 | 1-1/2″ | 73 | 1838 | 79 | 2132 | 84 | 2426 | 89 | 2720 | 94 | 3015 | |||||||||

| 50 | 2″ | 122 | 3054 | 132 | 3553 | 140 | 4043 | 149 | 4533 | 157 | 5025 | |||||||||

| 65 | 2-1/2″ | 204 | 4902 | 220 | 5685 | 234 | 6368 | 248 | 7252 | 261 | 8040 | |||||||||

| 80 | 3″ | 345 | 7760 | 263 | 9000 | 280 | 10240 | 298 | 11480 | 313 | 12730 | |||||||||

| 100 | 4″ | 408 | 12260 | 439 | 14200 | 468 | 16160 | 496 | 19120 | 522 | 20100 | |||||||||

| 125 | 5″ | 611 | 18400 | 658 | 21300 | 702 | 24260 | 744 | 27200 | 783 | 30200 | |||||||||

| 150 | 6″ | 815 | 24500 | 878 | 28420 | 936 | 32340 | 990 | 36260 | 1044 | 40200 | |||||||||

| 200 | 8″ | 1427 | 47000 | 1536 | 56850 | 1638 | 64680 | 1735 | 72520 | 1827 | 80400 | |||||||||

| 250 | 10″ | 2038 | 73520 | 2195 | 85270 | 2340 | 97000 | 2480 | 108780 | 2610 | 120600 | |||||||||

| 300 | 12″ | 2446 | 110300 | 2634 | 127900 | 2808 | 145530 | 2975 | 163200 | 3132 | 180900 | |||||||||

| 尺寸 | 水(25℃) M3/Hr |

氣體 M3/Hr (校準介質:空氣@ 20℃101325Pa環境) |

|||

| (mm) | Inch | 標準式 | 擴散式 | ||

| 15 | 1/2″ | 0.3~6 | 0.5~8 | 6~40 | 5~50 |

| 20 | 3/4″ | 0.6~12 | 0.6~12 | 8~50 | 6~60 |

| 25 | 1″ | 1.2~16 | 0.8~16 | 10~80 | 8~120 |

| 32 | 1-1/4″ | 1.6~30 | |||

| 40 | 1-1/2″ | 2~40 | 2~40 | 25~200 | 20~300 |

| 50 | 2″ | 3~60 | 2.5~60 | 30~300 | 25~500 |

| 65 | 2-1/2″ | 5~100 | 4~100 | 50~500 | 40~800 |

| 80 | 3″ | 6.5~130 | 6~160 | 80~800 | 60~1200 |

| 100 | 4″ | 15~200 | 8~250 | 120~1200 | 100~2000 |

| 125 | 5″ | 20~340 | 12~400 | 160~1600 | 150~3000 |

| 150 | 6″ | 30~450 | 18~600 | 250~2500 | 200~4000 |

| 200 | 8″ | 45~800 | 30~1200 | 400~4000 | 350~8000 |

| 250 | 10″ | 65~1250 | 40~1600 | 600~6000 | 500~12000 |

| 300 | 12″ | 95~2000 | 60~2500 | 1000~10000 | 600~16000 |

| 插入型使用 | |||||

| 300 | 12″ | 100~1500 | 1560~15600 | ||

| 350 | 14″ | 140~2300 | 2100~21000 | ||

| 400 | 16″ | 180~3000 | 2750~27000 | ||

| 450 | 18″ | 240~3800 | |||

| 500 | 20″ | 300~4500 | 4300~43000 | ||

| 600 | 22″ | 450~6500 | 6100~61000 | ||

| 800 | 24″ | 750~10000 | 11000~110000 | ||

| 1000 | 26″ | 1200~1700 | 17000~17000 | ||

訂購型號

| 訂購型號 | |||||||||||||

|

編碼 | 接口方式 | |||||||||||

| F | 法蘭式類型(標準型) | ||||||||||||

| W | 對夾式類型 | ||||||||||||

| I | 插入式類型 | ||||||||||||

|

|

編碼 | Piping Size | |||||||||||

| XXXX | 15~300mm(針對法蘭式) | ||||||||||||

| XXXX | 15~300mm(針對對夾式) | ||||||||||||

| XXXX | 300~1000mm(針對插入式) | ||||||||||||

|

|

編碼 | 材質 | |||||||||||

| 4 | SUS304(法蘭式&插入式類型) | ||||||||||||

| 1 | SUS301(對夾式類型適用) | ||||||||||||

|

|

編碼 | 接續方式 | |||||||||||

| 1 | PN10(針對法蘭式類型適用) | ||||||||||||

| 2 | PN16(針對法蘭式類型適用) | ||||||||||||

| 3 | PN25(針對法蘭式類型適用) | ||||||||||||

| 4 | PN40(針對法蘭式類型適用) | ||||||||||||

| A | ANSI 150#(針對法蘭式類型適用) | ||||||||||||

| B | ANSI 300#(針對法蘭式類型適用) | ||||||||||||

| C | ANSI 600#(針對法蘭式類型適用) | ||||||||||||

| J | JIS10K(針對法蘭式類型適用) | ||||||||||||

| K | JIS20K(針對法蘭式類型適用) | ||||||||||||

| L | JIS40K(針對法蘭式類型適用) | ||||||||||||

| N | 對夾式&插入式類型 | ||||||||||||

| Z | 其他 | ||||||||||||

|

|

編碼 | 感測器功能 | |||||||||||

| 1 | 流量顯示(無 溫度/壓力補償) | ||||||||||||

| 2 | 流量顯示+溫度+壓力計算 | ||||||||||||

| 3 | 流量顯示+溫度感測器 | ||||||||||||

| 4 | 流量顯示+壓力感測器 | ||||||||||||

|

|

編碼 | 輸出訊號 | |||||||||||

| A | 4~20mA(標準型) | ||||||||||||

| P | 脈衝 | ||||||||||||

| R | RS-485 | ||||||||||||

| W | Wifi | ||||||||||||

|

|

編碼 | 最大耐溫 | |||||||||||

| 1 | -40~280 | ||||||||||||

| 2 | -40-420(法蘭式 有 溫度/壓力感測器) | ||||||||||||

| 3 | -40-420(法蘭式+壓力感測器) | ||||||||||||

| 4 | -40~420(對夾式+壓力感測器) | ||||||||||||

|

|

編碼 | 保護等級 | |||||||||||

| N | IP65(標準型) | ||||||||||||

| I | Intrinsically Safe,E ex ia IIC T4 | ||||||||||||

| X | Explosion Proof,Exd IIC T6 | ||||||||||||

|

|

編碼 | 選購本體 | |||||||||||

| N | 無 | ||||||||||||

| R | 縮管型 | ||||||||||||

|

|

編碼 | 廠牌 | |||||||||||

| F | FGT | ||||||||||||

| N | 印刷客製廠排 | ||||||||||||

|

|

|||||||||||||

| FVF | 完整下單型號 | ||||||||||||

| *注意:全部型號支援電壓(+12~24 Vdc) | |||||||||||||

| *注意:使用客制化廠牌年購單需達100組以上 | |||||||||||||

符合設計標準

符合設計標準

符合設計標準

- EX-ATEX

- IP67

- BSMI

- CE

- IEC

- SGS

支援通訊協議

- NB-IOT

- MODBUS-RTU

- ZIGBEE