FGT think your best choice in the future

System Integration Designers in FGT

TMFC300質量流量控制器特性|氣體流量控制

- 低流量下的高精度

- 快速響應(≦1.0)

- 提供寬壓力範圍(1300 PSIG)

- 無洩漏

- 無需溫度或壓力

- 連接兼容

- 高穩定性可拆卸傳感器

- 耐腐蝕值

- 出色的線性度

- 出色的長期穩定性

- 模塊化設計

- 緊湊型流量控制系統

產品影片

好處:

質量流量控制器應用

- 電漿清洗機

- 氣體分流閥箱/盤

- 氣瓶櫃輸出流量控制

- 氣體產生機輸出控制

- 火焰焊接控制

TMFM/TMFC系列存在哪些類型的質量流量控制器?

熱質量流量控制器使用氣體的熱質感測技術來控制它們的質量流量。在 TMFC產品組合中,我們有多個熱質量流量控制器,每個控制器都有自己的傳感器技術:

使用旁路傳感器的質量流量控制器。這些設備(如TMFC和TMFM)非常適合清潔和乾燥氣體應用,在這些應用中需要更高的精度和可重複性。

使用在線原理的質量流量控制器。如果您的應用具有99.9%以上高純度的氣體,或者當高重複性和穩健性比精度更重要時,TMFC 和TMFM系列等系列是完美的選擇。

使用配管控制技術的氣體質量流量控制器。這些系列脫穎而出,因為它們可以測量氣體流量和控制。

只要您的質量流量需要顯示並流量範圍很大時,那麼使用 MEMS 芯片傳感器技術(例如TMFM6000)的氣體系列就是完美的選擇。

使用在線 (CMOS) 技術的氣體質量流量控制器。

質量流量控制器( MFC )原理/流量控制器原理

質量流量控制器( MFC )是一種用於測量和控制液體和氣體流量的設備。[1]質量流量控制器經過設計和校準,可在特定流量範圍內控制特定類型的液體或氣體。MFC 可以在其滿量程範圍的 0% 到 100% 之間設定一個設定點,但通常在滿量程的 10% 到 90% 範圍內運行,從而獲得最佳精度。然後,該設備將控制流速至給定的設定值。MFC 可以是模擬的或數字的. 數字流量控制器通常能夠控制一種以上的流體,而模擬控制器僅限於其校準的流體。

所有質量流量控制器都有一個入口端口、一個出口端口、一個質量流量傳感器和一個比例控制閥。MFC 配備了一個閉環控制系統,該系統由操作員(或外部電路/計算機)提供一個輸入信號,該信號與質量流量傳感器的值進行比較,並相應地調整比例閥以達到所需的流量。流量指定為其校準滿量程流量的百分比,並作為電壓信號提供給 MFC。

質量流量控制器要求供應氣體或液體處於特定壓力範圍內。低壓將使 MFC 的流體耗盡並導致其無法達到其設定點。高壓可能導致流速不穩定。有許多不同的技術可以幫助測量流體的流量並最終幫助控制流量。這些技術定義了質量流量控制器的類型,它們包括壓差(ΔP)、溫差 (ΔT)、科里奧利力、超聲波、電磁、渦輪等。

質量流量計安裝

現在質量流量計的應用場合越來越多,而一些初次安裝質量流量計的場合因為不清楚質量流量計的安裝方式,裝反、裝錯等現象,影響設備的正常使用,本文就這種問題詳細介紹一下質量流量計的安裝方式。

在傳感器安裝時過大的機械應力會影響質量流量計的零點,如果這些應力是不斷變化的,儀表將出現零點漂移進而導致儀表測量不準,無法正常工作。因此質量流量計的正確安裝,是保證設備正常運行的重要一環。

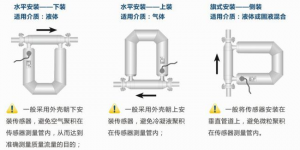

一,安裝方式選擇

傳感器的安裝方式主要根據流體的相別及其工藝情況確定,有三種安裝方式。

1、若被測流體是液體,一般採用外殼朝下安裝傳感器,避免空氣聚積在傳感器振動管內,從而達到準確測量質量流量的目的。

2、如果被測流體是氣體,一般採用外殼朝上安裝傳感器,避免冷凝液聚積在傳感器振動管內。

3、如果被測流體是液固體的混合漿液時,將傳感器安裝在垂直官道上,這可避免微粒聚積在傳感器科氏力測量管內。此外,如果工藝管線需要用氣體和蒸汽清掃,這種安裝方式還可以便於清掃,但這種安裝方式較前兩種難於固定,且壓損較大。

氣體流量控制器

氣體質量流量控制器 gas mass flow controllers

質量流量公式

質量流量計種類

質量流量計英文

按三度漢語網.多種解釋 mass flowmeter【電子計算機名詞】mass flow meter【機械工程】mass flowmeter sensor【海洋科學名詞-水下工程】thermal mass flow【電子工程】mass flow measurement【電機工程】

| 控制 | IOT, MCU, PLC |

|---|---|

| 應用 | 流量 |

| 類型 | 電子式 |

| 安裝方式 | 牙口 |

| 輸出方式 | 數位, 類比 |

技術規格

| Model | TMFC300V | TMFC300VD | TMFC300A | TMFC300A | |

| Flow Range(N2) | 100~300SLM | 100~300SLM | 100~300SLM | 100~300SLM | |

| Response Time | ≦2.0 sec | ||||

| Accuracy | ±1.0 % FS | ||||

| Repeatabllity | ±0.25 % FS | ||||

| Proof Pressure | 1500 PSI | ||||

| Leak rate | 1 x 10-9 atm.cc/sec or less | ||||

| Working temperature Range | 0~50℃ | ||||

|

Materials of parts in contact w/gases |

Body:SUS316 | ||||

| Valve seat:Vition(Option Bura or Kalrez or Teflon) | |||||

|

Joint |

Standard:3/8″ compression | ||||

| Option: 1/8″Compression or VCR,1/4″Compression or VCR VCR,3/8″ VCR | |||||

| Electrical connections | Dsub 15-pin male connector per standards | ||||

| Flow rate input signals | 0~5 Vdc | 0~5 Vdc+RS-485 | 4~20mA | 4~20mA+RS-485 | |

| Flow rate output signals | 0~5 Vdc | 0~5 Vdc+RS-485 | 4~20mA | 4~20mA+RS-485 | |

| required power supply | +15~28 Vdc/350mA | ||||

|

Option display |

Use to Type | ◎Yes | No | ◎Yes | No |

| Display interface | Option:Interface or Separate Type(With Cable Line 1M or 3M) for TMFC300V/A only | ||||

| communication Interface | Digital: RS485 (default) / DeviceNet for TMFC300V/A only | ||||

| Power supply | AC110~240 V for TMFC300V/A only | ||||

|

Coming Soon Function |

|||||

應用

什麼是MFC

質量流量控制器 (MFC) 是一種用於測量和控制氣體流量的設備。[1] 質量流量控制器經過設計和校準,可在特定流量範圍內控制特定類型的液體或氣體。 MFC 可以在其滿量程範圍的 0% 到 100% 之間設定一個設定點,但通常在滿量程的 10% 到 90% 範圍內運行,從而獲得最佳精度。 然後,該設備將控制流速至給定的設定值。 MFC 可以是模擬的也可以是數字的。 數字流量控制器通常能夠控制一種以上的流體,而模擬控制器僅限於其校準的流體。

所有質量流量控制器都有一個入口端口、一個出口端口、一個質量流量傳感器和一個比例控制閥。 MFC 配備了閉環控制系統,該系統由操作員(或外部電路/計算機)提供輸入信號,該信號與質量流量傳感器的值進行比較,並相應地調整比例閥以達到所需的流量。 流量指定為其校準滿量程流量的百分比,並作為電壓信號提供給 MFC。

質量流量控制器要求供應氣體或液體處於特定壓力範圍內。 低壓將使 MFC 的流體耗盡並導致其無法達到其設定值。 高壓可能導致流速不穩定。

MFC應用程序

1.CVD機

什麼是化學氣相沉積

化學氣相沉積 (CVD) 是一種真空沉積方法,用於生產高質量、高性能的固體材料。 該工藝通常用於半導體行業生產薄膜。

在典型的 CVD 中,晶圓(基板)暴露於一種或多種揮發性前體,這些前體在基板表面反應和/或分解以產生所需的沉積物。 通常,還會產生揮發性副產物,這些副產物會被流過反應室的氣流去除。

微加工工藝廣泛使用 CVD 沉積各種形式的材料,包括:單晶、多晶、非晶和外延。 這些材料包括:矽(二氧化矽、碳化物、氮化物、氮氧化物)、碳(纖維、納米纖維、納米管、金剛石和石墨烯)、碳氟化合物、燈絲、鎢、氮化鈦和各種高 k 電介質。

2.閥組箱/面板(VMB/VMP)

什麼是VMB/VMP

通過我們處理氣體的經驗,我們獲得了設計和製造EPI系統和MOCVD的氣體面板(氣體箱),材料供應系統等的知識。

在我們的業務成就中,我們能夠設計和製造以滿足客戶的要求(價格和規格)。 我們不僅可以處理普通氣體,還可以處理液化氣體的輪轂環空氣供應。 我們還支持各種法律申請。

流量範圍

| Model | TMFC300V | TMFC300VD | TMFC300A | TMFC300A | |

| Flow Range(N2) | 100~300SLM | 100~300SLM | 100~300SLM | 100~300SLM | |

| Response Time | ≦2.0 sec | ||||

| Accuracy | ±1.0 % FS | ||||

| Repeatabllity | ±0.25 % FS | ||||

| Proof Pressure | 1500 PSI | ||||

| Leak rate | 1 x 10-9 atm.cc/sec or less | ||||

| Working temperature Range | 0~50℃ | ||||

|

Materials of parts in contact w/gases |

Body:SUS316 | ||||

| Valve seat:Vition(Option Bura or Kalrez or Teflon) | |||||

|

Joint |

Standard:3/8″ compression | ||||

| Option: 1/8″Compression or VCR,1/4″Compression or VCR VCR,3/8″ VCR | |||||

| Electrical connections | Dsub 15-pin male connector per standards | ||||

| Flow rate input signals | 0~5 Vdc | 0~5 Vdc+RS-485 | 4~20mA | 4~20mA+RS-485 | |

| Flow rate output signals | 0~5 Vdc | 0~5 Vdc+RS-485 | 4~20mA | 4~20mA+RS-485 | |

| required power supply | +15~28 Vdc/350mA | ||||

|

Option display |

Use to Type | ◎Yes | No | ◎Yes | No |

| Display interface | Option:Interface or Separate Type(With Cable Line 1M or 3M) for TMFC300V/A only | ||||

| communication Interface | Digital: RS485 (default) / DeviceNet for TMFC300V/A only | ||||

| Power supply | AC110~240 V for TMFC300V/A only | ||||

|

Coming Soon Function |

|||||

訂購資訊

| Order Information | |||||||||||

| TMFC | Code | Flow Range | |||||||||

|

|

125 | 30~100SLM | |||||||||

| 300 | 100~300SLM | ||||||||||

| 500 | 300~1000SLM | ||||||||||

|

|

Code | In/Out Signal | |||||||||

| V | 0~5Vdc(Standard Type) | ||||||||||

| A | 4~20mA | ||||||||||

| VD | 0~5Vdc+RS-485(Can’t use to option display type) | ||||||||||

|

4~20mA+RS-485(Can’t use to option display type) | ||||||||||

| Code | Fitting Size | ||||||||||

| 2 | 1/8″ | ||||||||||

| 4 | 1/4″ | ||||||||||

| 6 | 3/8″(Standard Type for TMFC125/300) | ||||||||||

| 8 | 1/2″(Standard Type for TMFC500) | ||||||||||

|

|

Code | Fitting Type | |||||||||

| A | Compression SWL | ||||||||||

| V | Male VCR | ||||||||||

|

|

Code | Seal | |||||||||

| V | Viton(Standard Type) | ||||||||||

| B | Buna | ||||||||||

| K | Kalrez | ||||||||||

| T | Teflon | ||||||||||

| Code | Option Display Function#1 | ||||||||||

| N | Without(Standard Type) | ||||||||||

| I | Interface Type | ||||||||||

| D | Separate Type with Cable Line 1M | ||||||||||

| E | Separate Type with Cable Line 1M | ||||||||||

| Code | Option Display Remove#2 | ||||||||||

| R | Digital RS485(Standard Type) | ||||||||||

| D | Device Net | ||||||||||

|

|

|||||||||||

| TMFC | Complete Ordering Code | ||||||||||

| *Note:All Model come with Power Supply(+15~28 Vdc/350mA) | |||||||||||

| *Note:Using customer Logo launch to more than 100 united for one year | |||||||||||

認證