FGT think your best choice in the future

System Integration Designers in FGT

智慧建築自動化

系統整合設計

IoT 客製化設計

智慧製造自動化

FGT 機電工程系統設計|流量計生產製造

FGT®【第一通用科技有限公司】MEP機電工程的系統整合製造商

(流量計,SCADA / HMI系統,多點溫度控制器)製造生產公司

[專業MEP機電工程系統整合| 流量計製造商]

專業製造商生產水流量計,氣體流量計,AI人工智慧建築系統的工程設計,中央監控系統設計,智慧溫度控制器,IoT物聯網和APP軟體生產設計製造商

建築弱電事業群

弱電工程|營運內容

符合

台灣區智慧建築標章等級設計:銀級,黃金級,鑽石級

國際LEED等級設計:美國緑建築認證LEED · 40 – 49 分:合格認證 · 50 – 59 分:銀級認證 · 60 – 79 分:金級認證 · 80分以上:白金級認證

FTTH光纖到府: 由MDF/OLDF設計符合NCC送審標準

針對地下室及電梯行動通訊訊號強波器改善設計

包含槍型攝影機,半球攝影機等IP POE數位監視系統,DRV及NVR數位錄放影機,IVS電子圍籬

車牌辨識與Etag並行作業雙系統設計,車道管理及停車收費管理設計

嵌入式錄音系統(EmbeddedSystem)觸控式電話錄音答錄機USB錄音盒

氣吹式光纖施工,微簇型光纖施工

DTV數位頻道與BS衛星天線設計施工

大樓全網型影視對講系統包含大門口機,小門口機,室內對講機設計規畫施工

IP廣播模組. MD-1. 吸頂式喇叭. 壁掛式喇叭. IP廣播模組. MD-1. IP廣播模組. MD-1. 喇叭. 鵝頸式. 麥克風. 音源輸入. 音源輸入. 廣播區域. 切換器. 音樂撥放. 時間清單

UHF由於的波長較短的特性所以穿透性較強,適合用在有較多障礙物的室內場域,例如工程營造、工廠監控、保全巡守、餐廳、KTV、飯店、酒店等室內或樓層較多的場合;另外業務型免執照無線電對講機的使用頻率也是屬於UHF的範圍內

弱電整合系統界面說明. 1、 A 區宅內智能箱系統. 本系統具宅內智能箱模組設備,其界面說明如下:. (1) 網路模組. 本設備是由共同天線弱電製造商提供,光世代數據交換機 .

完整企業級 IP-PBX 產品: IP-PBX是企業VoIP 系統的核心,它能夠擴充企業語音電話的特色與功能,涵蓋完善的數據、語音、及視訊服務,如整合通訊(Unified Messaging)等特色。更包含以下特殊功能:

‧ 自動分機設定 (Auto Provision)

‧ 個人化設定多國語言自動總機功能 ( Auto Attendant)

‧ 多人語音會議 (Meet-Me)

‧ 即時通話錄音(Recording)

還提供了其他進階功能例如:三層自動總機語音應答系統(IVR)、語音會議室、通話駐留以及可以用電子郵件通知未讀取語音留言或以附件方式將未讀取語音檔寄出的語音留言系統及網頁式管理介面等傳統交換器無法提供的進階功能。IPBX-1825 也提供了可擴充的 FXO 或 FXS 介面,是非常穩定的嵌入式系統。所有的系統設定、語音留言以及通話紀錄都可儲存在其他外接式儲存設備。管理員可以將系統設定檔透過網路管理介面備份到自己的電腦。萬一系統受損,管理者只需將系統備份回覆。

智慧大樓之電力、中央空調、照明、衛生給排水、 送排風、電梯、消防系統均可納入中央監控系統,至少具設備使用狀態與故障監視及事件發生之處置及歷史紀錄功能

專業設計跨國多語系App使住戶多國語系均可具有對居民、管委會、物業公司、周邊店家各方立場通盤照顧的設計

全方位掌握水、電、氣、熱等建築內部能源,整合統計分析資料,提供能耗指標/異常診斷/能源預警。結合配電、供水、空調等系統,量化管理xAI模型對接,實現能源預測、降耗應用,幫助企業善用資源。

生產事業群

流量計|控制盤|營運內容

工業中央監控事業群

機電中央監控系統整合|營運內容

- WebAccess <研華科技>

- Indusoft <泓格科技>

- IFIX <群泰科技>

- Intouch <科勝科技>

- FMCS400 <整廠監控>

- 各類儀器設備通訊協定轉換客制化

- MODBUS RTU/TCP 轉換服務

- OPC Client 通訊撰寫服務

- 圖控軟體元件外掛元件開發撰寫

- 軟體、硬體通訊介面驅動程式撰寫

- 控制器(PLC、PAC、DDC)韌體撰寫

- 網頁式監控圖形介面撰寫

- 資料庫軟體撰寫服務

- 圖控客制化或輔助報表軟體撰寫

- 雲端資料庫撰寫

- SIEMENS S7-400

- FATEK PLC

- AB Logix1400

- ORMON CJ2M

- ABB AC500

- 圖控系統輔助元件

- MODBUS 485輔助組件

- 4G/5G無線與NB-IoT輔助組件

- 門禁系統輔助元件

- Visual C#(通用程式編輯軟體)

- BCB C++(通用程式編輯軟體)

- HTML5(手機程式編輯)

- MySQL/ MS SQL / Oracle (資料庫語言)

- python (人工智慧深度學習編寫)

News

解鎖精確流量控制, TMFM5000 MEMS質量流量計與針閥完美搭配

FGT發布[TMFM5000 質量流量計]流量範圍: 可以從最小流量10sccm(標準立方公分每分鐘)到1200SLM(標準公升每分鐘)。 這表示它可以適用於從非常小的流量到相對較大的流量的測量

集合住宅|建設公司實績

集合住宅|建設公司實績|採用智慧化建築弱電設計|台灣建設公司|越南建設公司|中國建設公司|由FGT跨國集團旗下一起趣設計團隊設計承包

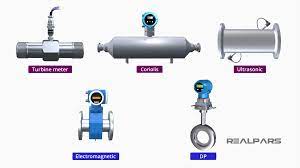

流量計種類概念-用途篇(一)

一張表格看懂流量計種類選擇:電磁流量計,卡門渦流流量計,質量流量計,葉輪流量計,渦輪流量計,面積流量計,膜片流量計,超音波流量計,科氏力流量計,皮託管流量計,孔板流量計,明渠流量計

我們的實績區域

TOP 500 品牌集團公司選擇與FGT集團合作

廣泛的服務組合

FGT為客戶提供全面的一站式工程設計和諮詢服務。 此外,FGT以非常稱職的方式管理專案所需的所有工程工作和專業技術。

提供氣體流量計,水流量計,廢水流量計,蒸氣流量計,電磁式流量計,渦流式流量計,質量式流量計,面積式流量計

供應氣動閥,電動閥,止回閥,角閥

供應PID溫度控制器,多點式溫度控制器

供應壓力開關,壓差傳感器,隔膜壓力表,真空壓力表

系統整合設計

> IoT APP開發設計 > AI解決方案 > 雲端系統

流量計和OEM/ODM解決方案

> 氣體流量計 > 水流量計

智慧製造自動化

> FMCS400中央監控系統 > TY08 / 15多溫度面板 > PLC程式設計 > SCADA圖控設計 > 氣體分配盤 > 控制盤

我們的實績

我們將合適的人召集起來,挑戰既定的思維方式和促進轉換成效